News and features on food processing and supply chain issues in the food industry.

Baking & Snack

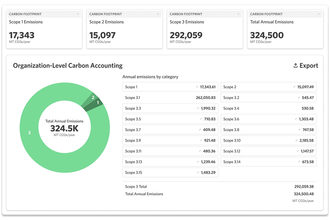

Computers and Controls

New software can increase efficiencies and automate processes.

Videos

More VideosGalleries

CII opens new facility for granola, clusters

Future lines may handle heat-treatment system, textured plant protein.