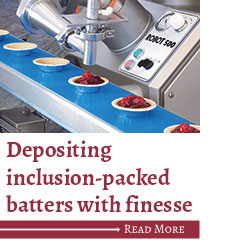

Everyone knows that big things often come in small packages. But sometimes lots of things — fruits, nuts and other particulates — come in them, too. Mini and single-serve products such as muffins that are formulated with inclusions require specific processing considerations, especially in terms of their deposits.

In some cases, as with gourmet and specialty items, the size of the finished baked food might not dictate the size of the inclusion. In fact, consumers sometimes have an expectation — realistic or otherwise — that even a product that fits into the palm of their hand should pack in as many chunks, strands or crunchy bits as possible.

“With mini, single-serve products, the margin for error is very tight, especially with inclusions,” said Lance Aasness, executive vice-president, Hinds-Bock. High tolerance, gentle handling and, of course, precision are of the utmost importance for bakers to ensure inclusions are adequately deposited with the batter and that consumers are getting the most bang for their buck in a smaller-sized product.

Mini products often come in large packs, such as a dozen mini muffins sold in the in-store bakery; in these cases, uneven distribution of inclusions like nuts or chocolate chips will become painfully obvious. Alternately, smaller or single-serve items with too little or too much of an inclusion can diminish the user experience. Not only that, but, as with any deposited product, inaccurate portions also lead to either short-changing the customer or giving product away.

“If you’re producing a mini muffin with blueberry or nut inclusions, and the product in the hopper is not properly and gently agitated, you could get deposits with large amounts of inclusions and others with little or no inclusions,” Mr. Aasness said. “Hinds-Bock designs hoppers with built-in product agitators that gently mix the product in the hopper so that all the inclusions are equally suspended throughout the batter. This process helps ensure that all your deposits have equal amounts of inclusions.”

For Reiser, mechanical and vacuum assists feed its double-screw depositor for better accuracy.

“Once the double-screw is filled, we can precisely turn the screw to make exact-weight portions reliably and repeatedly,” said John McIsaac, vice-president, strategic business development, Reiser. Reiser’s Vemag was designed to handle these types of thick and viscous batters.

While some bakers believe there’s no such thing as too many inclusions and want to cram as much good stuff into the product as possible, others believe that’s not always the case.

“We try to accommodate with different double screws tailored to the product weight and desired inclusions,” Mr. McIsaac noted.

Stewart MacPherson, owner and vice-president, sales and marketing, Unifiller, said the key to even distribution begins with the ingredients. He noted that if bakers source ingredients that come in the form of large chunks, they must be mindful of the deposit requirements. For example, a 14-gram deposit with large inclusions that could weigh an average of 20 grams just doesn’t compute.

“The best we can do is cut off half a chunk at the end of the fill process,” he cautioned. “Therefore, when trying to fill a small portion with oversized chunks, the customer might be better off sourcing the filling with smaller particles that will increase the accuracy of the deposit.”

Hans Besems, senior application specialist, Tromp Group, also noted that inclusions oversized for a smaller deposit can hinder accuracy.

“This is because it will decrease the viscosity in the batter or mix,” he said. “The key is to make sure the batter is released correctly from the depositor. We designed our system to handle small fillings by making specific components smaller to ensure correct weight accuracy.”

Precise weights and even distribution start in the mix, said Cesar Zelaya, bakery sales and technology manager, Handtmann.

“Handtmann depositors feature different types of agitators in the hopper with variable RPM to maintain particles in suspension while the batter rests in the hopper,” he said. “This allows the baker to have a similar count of particles in each deposit with accuracy within 1%.”

The company offers a variety of discharge valves, including dripless, inverted piston, rotary and dividing heads to maintain this level of accuracy.

For some bakeries, smaller-sized products are made in a comparable-sized operation. In these cases, items that come with inclusions are often deposited by hand to carefully handle those delicate pieces and ensure even distribution.

Although these methods can be quite helpful for miniaturized baked foods, it may not be a sustainable solution as output increases.

When this happens, bakers must first understand the tradeoff for efficiency. If the operation is streamlined and the products become more consistent, sometimes automation will result in a slightly different finished product. That said, different doesn’t have to equate to bad. It just might require some expectation management and a bit of homework before settling in.

“When you transition from a manual operation to semi- or fully automated, the product may change a little because it’s now going through a machine,” Mr. Zelaya said. “At Handtmann, we always encourage customers to test their products on the equipment before purchasing. We strive to make as close to the same product as the original hand-made version as possible.”

To accomplish this, Handtmann offers custom designs.

“Our depositors can produce a variety of shapes and feature different diameters to accommodate any specific pan cavity shape, size or pattern,” Mr. Zelaya said. “We can also prevent any clogging regardless of particle size.”

“Our depositors can produce a variety of shapes and feature different diameters to accommodate any specific pan cavity shape, size or pattern,” Mr. Zelaya said. “We can also prevent any clogging regardless of particle size.”

Mr. Besems also advised bakers who are ready to take a step toward automation to accurately understand their starting point.

“Make sure you know what you need to deposit, and what’s the giveaway,” he said. “How much overweight was happening with a manual deposit? When you know this, you can more accurately determine if automation will give you the expected return on your investment.”

Testing is also at the top of the list for Reiser, said Mr. McIsaac, who suggested that bakers test equipment before purchase and ask for a guarantee of satisfaction.

“We have customers visit our Reiser Customer Center daily,” he said. “We mix and run their products on the machines we are proposing so they can see for themselves and then confidently install it in their plant.”

Among Hinds-Bock’s variety of depositing equipment is a hand-held nozzle with a positive shutoff spout assembly.

“This is best suited for hitting small targets like mini-muffin pans or spot depositing fruit filling, it gives you accurate and quick hand placement for depositing,” Mr. Aasness said.

When moving into automation, bakers must remember that the formula rules.

“At the end of the day, that’s the decision maker,” said Matteo Grandi, communication and marketing specialist, Minipan, which manufactures volumetric depositors. “Automation has a lot of advantages, even for small bakers: more productivity, more accuracy, more consistency of product, less waste, less handwork and less fatigue.”

It’s true that bakers of any size can fit a lot into a small product. And with thoughtful planning and careful depositing, they can make a tiny product go a long way.