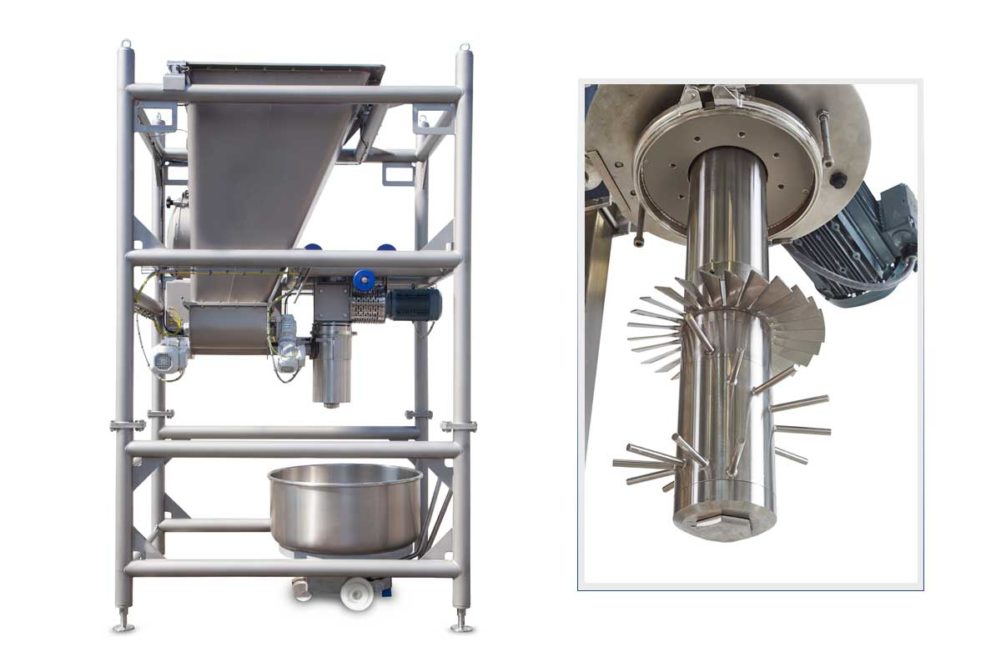

DymoMix from Zeppelin Systems USA was designed to increase dough production in a dust-free environment, reduce energy consumption and minimize costs. The prehydration system works by adding moisture evenly through free-falling dry materials with water, cream yeast and other water-soluble ingredients. This instantaneous biochemical process generates a homogenous dough within seconds.

“The DymoMix was originally conceived as a way to create dustless flour, but Zeppelin quickly realized it had a much broader range of applications, not only in hydrating flour but also on a variety of other applications where quick and thorough dispersion of a liquid on dry powders is required,” said Joe Cross, engineering and process manager, Zeppelin Systems USA. “Our technology is unique in that we can successfully disperse not only water, but a variety of water-based solutions and suspensions or even oil or liquid fat.”

The dough can either be used instantly or transferred to a batch or continuous mixer. The machine can be used in all bakery sizes, from small companies up to large industrial operations needing to make up to 5 tons of liquid sponge or sponge-and-dough per hour.