Reclosable packaging is typically introduced for one of two situations: a new packaging design for an existing product or an entirely new launch. In either case, a simplified user experience may well require some complexity on the packaging line, so bakers must be prepared.

“Reclosability can make the processing line a little more complicated,” said Dennis Gunnell, president, Formost Fuji. “It all depends on what reclosable feature you add and its level of complexity.”

Bakers often default to what they’re most familiar with, such as the zip lock. “That’s because it’s universally known,” Mr. Gunnell suggested.

However, familiar doesn’t necessarily equate to easy, and adding a zipper to a wrapper is not a “set it and forget it” type of application.

“If you’re applying the zipper on the machine as you’re running, it takes an operator who knows what he or she is doing to keep it running smoothly,” Mr. Gunnell said.

It’s possible to purchase the pre-applied film, but that could change how the material is stored and run on the line.

“You might have to make machine modifications to run a film with the zipper already applied,” Mr. Gunnell said.

So, while the intent is to make an easy user experience, bakers have a lot to consider before making that happen. They must do their homework first.

“Zippers are what everyone knows, but that’s not the only option,” Mr. Gunnell said, noting that bakers can rely on packaging equipment suppliers’ expertise to weigh all the options out there. “We suppliers can say, ‘Would “this” be a better option for you?’ And that’s when they start thinking about what else they could use.”

As technology advances in CPG, a plethora of reclosable options are available, ranging from zippers to seal strips to locks and twist ties.

“As a wrapper manufacturer, we have the capability to put features like a zipper on,” Mr. Gunnell explained. “We don’t make those units, but we can interface them with the wrapper. We can add a zipper, resealable label or seal-strip tape. All these have been applied on our wrapper as the line’s been running.”

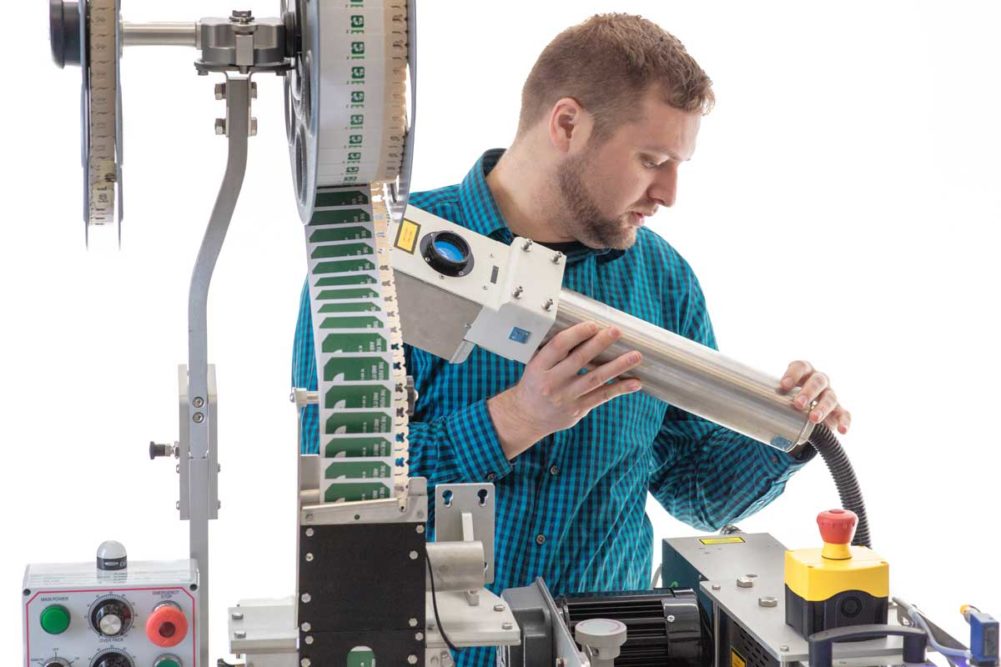

Formost Fuji has partnered with Reseal-it by McFarlane Label on various customer projects. Angela Campbell, Reseal-it director, emphasized that when incorporating new reclosability to packaging, the new process should not sacrifice line speed. Reseal-it offers inline and stand-alone machinery to match the needed functionality with the current flexible film package by applying a label and undercutting it to ease opening.

Bedford Industries also offers several options for reclosability, including metal and non-metal twist ties as well as the Double Wire Tin-Tie that runs across the top of a bag such as those used to package donuts, as well as a Roll N Close option for similar applications.

While reclosability can make life simpler for the consumer and a bit more complicated for the operator, automation can ease that baker’s burden.

“It’s all about automation,” said Ron Cardey, senior vice-president, customer engagement, Kwik Lok. “Bakers need equipment that works every day and that doesn’t break down or call in sick.” Automation in reclosable packaging means reliability for the baker and the end user, and that’s a win-win.

This article is an excerpt from the March 2020 issue of Baking & Snack. To read the entire feature on reclosability, click here.