Creating a soft pretzel’s iconic taste, golden sheen and texture involves many careful calculations. Advances in caustic and lye application systems and robotic twisting machines, in addition to baker creativity, are producing improved pretzels ranging from dark and salty to light and soft — and twists far beyond the classic loop.

The traditional soft pretzel shape in the United States features the recognizable twist of a dough strand. The European version comes with a thicker middle portion of the dough knot. Today, bakers can take the dough and shape it into a variety of knots and braids to make any product stand apart.

“Pretzel dough can be made into various shapes, and that evolution seems to be never ending,” said Rick Liberatore, regional sales manager, Gemini Bakery Equipment/KB Systems.

That evolution is slow to catch on here compared with some parts of Europe, but it is happening.

“In the United States, mostly we are sticking with the well-known products,” said Matt Zielsdorf, director of bakery sales for Fritsch, a Multivac company. “Soft pretzels are offered at sporting events in the stadiums but also in the shopping malls where they are freshly made.”

[Related reading: Automated systems take control in developing new and improved soft pretzels]

This authentic in-person experience has always added to the appeal of pretzels. To recreate this experience for consumers at home, bakers can look to recent advances in manufacturing technology, specifically, Mr. Zielsdorf said, bakers’ use of the 5- to 7-inch “noodle” string of pretzel dough that can be automatically or manually tied.

“One can say that the noodle, in its various forms, has been an innovation,” he said. “The technology has become faster and more compact. Pretzels with large weights can now be produced. And the larger the pretzel, the more popular they seem to be.”

Turning that noodle into a plethora of pretzel products requires some strategic planning, beginning with formulation and mixing.

Dough deliberations

While the defining characteristic of a pretzel comes from a caustic bath, the dough itself is markedly different from a traditional bread or bun dough. Soft pretzel dough is typically much more dense.

John Eshelman, director of pretzel and snack machinery sales, Reading Bakery Systems (RBS), said hard and soft pretzel doughs are usually formulated with about a 40% hydration level. Bread doughs are often 60% hydration or more. Additionally, he said, protein levels in flour for pretzels is usually higher than bread. Where pretzel flour blends might have 14% protein levels, bread and bun doughs include just 8% protein.

“Pretzel dough is strong enough that it’s going to maintain its shape,” Mr. Eshelman said. “Whereas with a bread formula, if you would take it out of the pan, over a short period of time it’ll flatten out like a pancake.”

When creating dough ropes, or noodles, the length of the strands should be defined by the final desired size and weight of the pretzel.

To create consistent dough, Mr. Eshelman recommended a continuous mixer because the density, hydration and texture can be managed and controlled consistently.

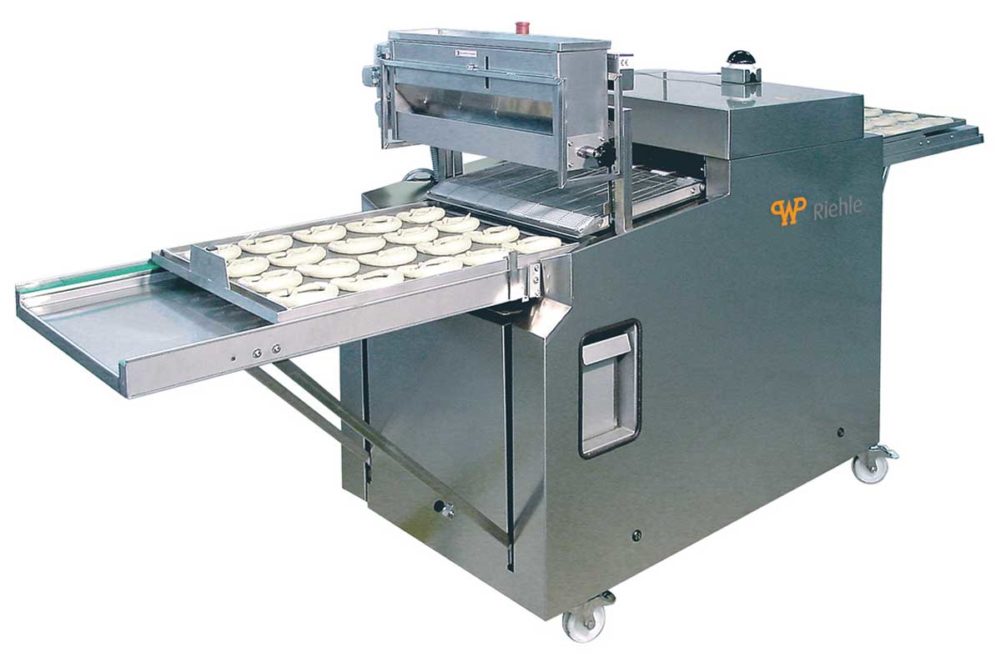

Franz Jordan, managing director, WP Riehle also recommended a mixer that minimizes dough heating. If the dough gets too warm, spots will appear on the final product. WP Kemper mixers have a spiral for pretzel dough that incorporates airflow to maintain lower dough temperatures.

Since soft pretzels are yeast-raised, proofing is required. Mr. Jordan explained that a good proofing chamber should have uniform air distribution with exact temperature and humidity control, ideally with an automatic transport system.

“The challenge is the uniformity of results during winter and summer,” he said. “Resting the dough in controlled ambience gives the right skin texture before lye application.”

Because the doughs are stiff and dry, they can create scaling challenges. Jay Fernandez, technical director at the Middleby Bakery Innovation Center, said product attributes such as crumb structure and texture are important to the consumer.

“Ingredient selection can assist the baker,” he said. “Proteases and deactivated yeast along with other relaxers help and allow for clean label claims, and the type of divider can play a key role.”

[Related reading: How pretzel makers are fighting off flat sales]

Stewart Systems, a Middleby Bakery company, and its Wave extrusion system can make soft pretzel dough balls and sheets and transform them into ropes at high speed. The system features large-diameter polymer double screws that rotate slowly and prevent the dough from sticking. The result, Mr. Fernandez said, is that the dough is exposed to lower pressure and can be cut at rates of up to 150 per minute on six to eight lanes.

The Vemag from Reiser also gently divides these stiff doughs. Operators can adjust the Vemag to run doughs ranging in hydration from 45 to 95%, said Jim Fontaine, bakery field sales manager, Reiser.

“The dough dividing equipment must have plenty of torque as well as a strong dough feed system and portioning system in order to accurately scale pretzel dough,” Mr. Fontaine said.

When creating dough ropes, or noodles, the length of the strands should be defined by the final desired size and weight of the pretzel.

“The consistency of the pretzels is important insofar as if the dough is too unstable, the product can lose its shape at transfer points,” Mr. Zielsdorf added.

And transfer points are critical because pretzels face a couple important detours before heading into the oven.

This article is an excerpt from the July 2020 issue of Baking & Snack. To read the entire feature on pretzel technology, click here.