On the highway to profitability, bakers keep pushing the limits on speed. Dividers, depositors and extruders — sometimes working in tandem — feed a seemingly insatiable interstate of conveyors to larger, wider and longer ovens and proofers.

However, faster is not always better, especially for pans that serve as the vehicles of the production line and bear the brunt of the daily bumper-car commute. Here, even the smallest breakdown can create a mile-long pileup that brings everything to a halt.

To apply a brake to the process and improve traffic flow, bakeries turned to wider, larger pans that still crank out a large volume of products at a more manageable pace.

“Bakeries have always tried to increase efficiencies and production, and the use of larger pans aids in that process,” noted Trevor Walker, vice-president of North American sales, Bundy Baking Solutions. “However, the challenge lies with the process and handling equipment. The pan size has increased, but the equipment that handles them has remained the same size. Oversized pans are traveling on smaller conveyors and making tighter turns within the routing process, which can cause more abrasions, scratches, handling abuse and wear on the pans.”

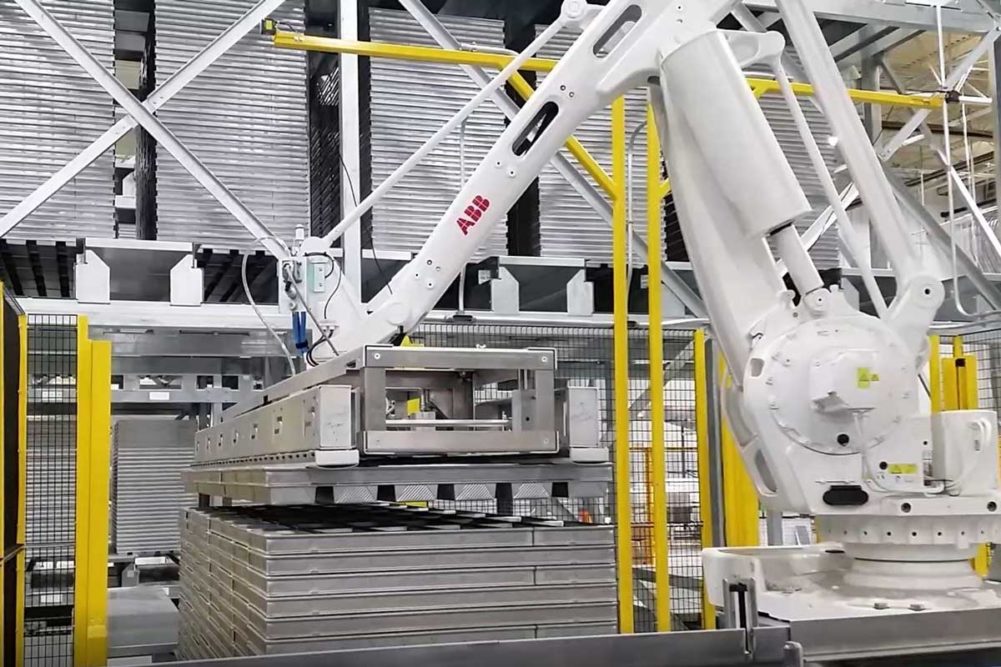

Moreover, these extra-wide “maxi” bun pans provide another challenge. For ones that are wider than 27 in. or longer than 44 in., a conventional pan stacker and unstacker no longer works, prompting bakers to rely on robotic technology, according to Mike Scouten, vice-president, sales and marketing, Stewart Systems and Baker Thermal, both Middleby Bakery companies.

“Stewart uses a specially designed robot end effector that uses a field magnet and does not touch the pan surface,” he said. “The robotic movement is all by servo so the precise placement of pans on stacks is maintained.”

Bruce Campbell, vice-president, dough processing technologies, AMF Bakery Systems, pointed out that robotic and gantry systems today handle large groups of all types of pan sizes, ensuring a controlled motion while moving them on and off the line. “This drastically extends the life of the pans,” he said.

Moreover, robotic technology is constantly getting better. “The improvements make it easier for the designers to program and bakers to operate them,” explained Bob Harrington, vice-president of sales and marketing, Capway Automation.

While the servo-controlled system can rapidly remove traditional sized pans on and off the stack or conveyor, the larger ones normally result in a lower pan-per-minute rate of operations, making it easier to operate.

“The robotic pans system also has minimal lateral movement when gently placing the pan onto the stack, which minimizes pan coating damage,” Mr. Harrington observed.

Frank Achterberg, president of CBF Bakery systems, suggested that robotic vertical stacking and unstacking also extends pan coating life.

“The robotic systems can be equipped with either mechanical, vacuum or magnetic type end-of-arm (EOA) tooling to ensure gentle handling of the pans,” he explained. “After the pans are stacked, they can be moved by means of conveyors or shuttles and stored away from the line. The option to stack upside down ensures no debris can collect in the top pan.”

But even the latest advances in technology can’t prevent breakdowns or other issues. That becomes a bigger problem with larger pans. “Many of these oversized pans running at higher speeds, in an emergency, cannot be manually stacked by one operator, so the reliability of the stacker is key for smoother operation,” said Dennis Kauffman, executive product manager, AMF Bakery Systems.

Failure to minimize pan damage and protect pan coatings often results in unintended expenses and hidden costs. That’s especially true on high-speed lines where even a small percentage of damaged product caused by nicks and scratches can add up exponentially to unnecessary waste. Moreover, frequent pan recoating due to improper pan handling and cleaning puts a dent into a bakery’s bottom line.

Mr. Walker advised that bakeries can extend coated pan life with proper care, good training and attention to material handling needs.

“Pans for high-volume products are great for non-stick coatings because the long runs keep pans in circulation, minimizing the number of times they are stacked/unstacked or manually handled,” he said. “Pans must nest freely without unnecessary pan-to-pan contact on their coated surfaces. This helps protect against scratches, handling abuse and premature failure of the coating. Also, the more bakeries can vertically depan the baked good, the longer the life of its pan and coating.”

Investing in robotics, however, may not be possible, especially for specialty bakeries, mid-sized operations and businesses that cannot afford the initial investment. In many cases, starting with conventional stackers and unstackers can be a suitable alternative that provides substantial savings to justify the capital expenditure.

“In many parts of the world, the cost of labor is driving a higher return on investment for automated pan systems,” Mr. Campbell said. “In addition, worker safety laws prevent manual handling of large, hot pans. And, with up-time a premium in this competitive market, quick changeovers to optimize line time make the need for automatic systems more important for bakers.”

In addition to gentle stacking, most automated systems have a pan inverter to allow stacking the pans on the heavy-duty rim for more support instead of the bottom of the mould, according to Mr. Kauffman.

“Stacks can be higher, thus reducing the number of pan trucks or floor space in multi-level storage systems,” he explained. “Years ago, most pans had bent moulds and bowed rims from stacking top-side up. Also, inverted pan stacking prevents debris and dust from accumulating inside the top pan on the stack.”

With its conventional pan stacker and unstacker, Stewart Systems now relies on a servo thruster that makes pan handling much gentler.

“This is due to precise motion control, as one might suspect,” Mr. Scouten said. “It also means a higher throughput can be realized. This is available on new units but also as an asked-for upgrade kit. When properly adjusted, our mechanical stackers already had provided long life on pans relative to hand stacking or other units available, but the servo thruster will even further extend the life of the pans.”

Pan damage can occur throughout the production line as they travel on conveyors, are stopped by gates and clamps, transfer points, oven loading, unloading, pan indexers and other traffic-control devices.

Mr. Achterberg noted, using plastic-type belts minimizes damage by reducing friction on the pan bottoms especially in accumulation areas where pans are indexed or backed up against one another. He suggested positioning gates and clamps so they interact with the pans’ bar bands, which are strong enough to handle these forces.

Capway Automation focuses on conveyor designs that allow constant easy flow of pan movement. “This requires smarter pan conveyor control systems and sensors throughout the conveying line that over time will yield savings based on minimal pan damage occurring,” Mr. Harrington said.

This article is an excerpt from the February 2020 issue of Baking & Snack. To read the entire feature on pan glazing, click here.