Although the United Dairy Farmers (UDF) had no prior experience in producing baked goods, the Cincinnati-based convenience store chain’s foray into donuts — square yeast-raised ones — dovetails nicely into its manufacturing business unit that supports its c-stores.

In addition to producing its own ice cream, UDF operates three cold storage warehouses for its dairy and frozen foods along with a complementary logistics operation that distributes gasoline, milk, ice cream, fresh foods and almost anything that’s not direct-store delivered.

Prior to opening the bakery, UDF had been shipping donuts from a local third-party bakery for a decade.

“We had that built-in quality that we could count on and thought that we could grow the business more significantly than what it was,” observed Brad Lindner, UDF’s chief executive officer. “We knew we could give donuts a lot more love and attention because they’re now part of our manufacturing operation. We’ve been selling a boatload of donuts for years.”

Still, he admitted, producing donuts — not just selling them — didn’t happen overnight, and the learning process continues as the bakery expands its fresh-baked offerings.

“It was an interesting journey to get into the baking industry, formulating recipes and deciding the different products to introduce,” Mr. Lindner recalled. “Obviously, we have taken a phased approach. We want to crawl and walk before we run. We’ve done that with the initial offering of donuts.”

UDF began exploring donut production back in 2018, when it hired Henry Lopez as a consultant to conduct a pro forma report on its burgeoning business. A former chief operating officer who oversaw bakeries and food manufacturing operations for another large c-store chain, Mr. Lopez spent months developing the business plan for a startup bakery. He is now the bakery’s plant manager.

Rene Lozano, UDF’s director of operations, noted that UDF had found itself at a crossroads a couple years ago.

“We knew that our contract with our donut supplier was reaching its end, and we had to figure what to do next,” he said. “Were we going to sign a new deal or figure out how to do it ourselves? We’ve never made donuts before, so we put a pro forma together and tried to figure out if that’s the right thing to do.”

After completing the plan, Mr. Lopez, Mr. Lozano and UDF’s management team weighed in on the results.

“Looking at what we were paying for donuts back then, the pro forma really didn’t tell us to go build a facility,” Mr. Lozano said.

Shortly afterward, Mr. Lopez added, UDF received the proposed new contract from its supplier, and that’s when everything changed.

“It was a two-week period where we said, ‘We can build a bakery for the cost of the supplier producing the donuts for us,’ ” he recalled.

Mr. Lozano then sketched out an initial design of the production facility, and turned to Jackson, Mich.-based Dawn Foods to discuss supplying ingredients for the custom formulas UDF had developed.

Shortly afterward in January 2019, Dawn Foods introduced Mr. Lozano to John Dairman, vice president of operations of Chandler, Ariz.-based Donut Peddler, who gladly offered advice on starting up a donut operation and provided a tour of the company’s bakery in Houston.

“Donut Peddler has several facilities, and like us, they deliver their products themselves,” Mr. Lozano said. “They were so helpful. They walked us through their process and gave us some guidance on what we needed. We had to be quick because this operation needed to be up and running by mid-2019.”

UDF’s real estate division then found the building location, which proved to be key for serving as a distribution hub for its donuts and other fresh foods. As far as equipment goes, the company needed an operation that was user-friendly and within its new level of expertise in the baking industry.

“We’re not a company with a lot of bakery experience, but since we have so much manufacturing experience, we knew what route we would be going down,” Mr. Lozano said. “That meant picking equipment that was efficient, quick-to-learn and user-friendly.”

Two weeks prior to startup, Mr. Lopez noted, the bakery began limited production.

“We were producing 4,000 donuts a day before going to a full launch just to get the team acclimated with running the equipment,” he said. “Then on day one, we were doing 12,000 donuts, or three times the volume we were doing before with this new equipment.”

The next day, UDF ran a promotion and gave away 10,000 donuts on top of the normal sales.

[Related reading: UDF doesn't cut corners with its donuts]

“We went from 12,000 to 24,000 on day two,” Mr. Lopez said. “The making of the donuts was the easy part. However, we had vice presidents, family members and even spouses helping us out because we had to pack and ship the donuts to every store.”

Mr. Lindner noted that it took an all-hands-on-deck approach to get the job done.

“Obviously, we had a deadline for when we were transitioning from our supplier,” he said. “That was a hard deadline for the transition, and by golly, everyone pitched in and did yeoman’s work to make that happen. But that get-it-done attitude is not uncommon here.”

Overall, the bakery pumps out up to 30,000 donuts seven days a week with a rotating days-off work schedule that allows the nearly 30 employees to have at least one weekend day off every other week.

“This allows us to maintain a more stable workforce,” Mr. Lopez said.

In addition to Mr. Lopez, overseeing the day-to-day operations are Daniel May, logistics and operations supervisor; Tony Grote, production supervisor; Dennis Fitch, chief engineer; James Allgeier, sanitation supervisor; and Mark Wilson, human resources manager.

Production in the multi-functional, semi-automated bakery runs on two staggered 8-hour shifts, starting at 3 a.m. followed by makeup and frying beginning around 4 a.m., and the remainder of the shift ramping up by 6 a.m. All products are shipped by mid-afternoon each day on UDF-owned trucks, and an 8-hour sanitation shift follows every evening. A Hildebrand tunnel washer cleans its trays and other components.

Inside the temperature-controlled room with a filtration system to purify the air, operators start producing a small amount of cake donuts as they prepare for yeast-raised donut production. Typically, it takes about 70 minutes to make up and proof the yeast-raised dough.

Initially, two Escher spiral mixers turn out about a dozen, 300-lb batches of dough daily. Production on the versatile Rademaker USA makeup line starts with Bismarks and Long Johns, which require a longer proofing, followed by chocolate and iced donuts before a long run of glazed donuts, cinnamon rolls and the kettle or fried croissant dough variety.

After resting the yeast dough, an operator manually chunks and feeds it onto a conveyor leading to a sheeter on the makeup line. The sheet travels through a quick-reduction system and trimming, where the scrap is recycled into subsequent batches as a part of the products’ formulas. Mr. Lopez noted that toolless replacement of cutters and other components allow for quick changeovers.

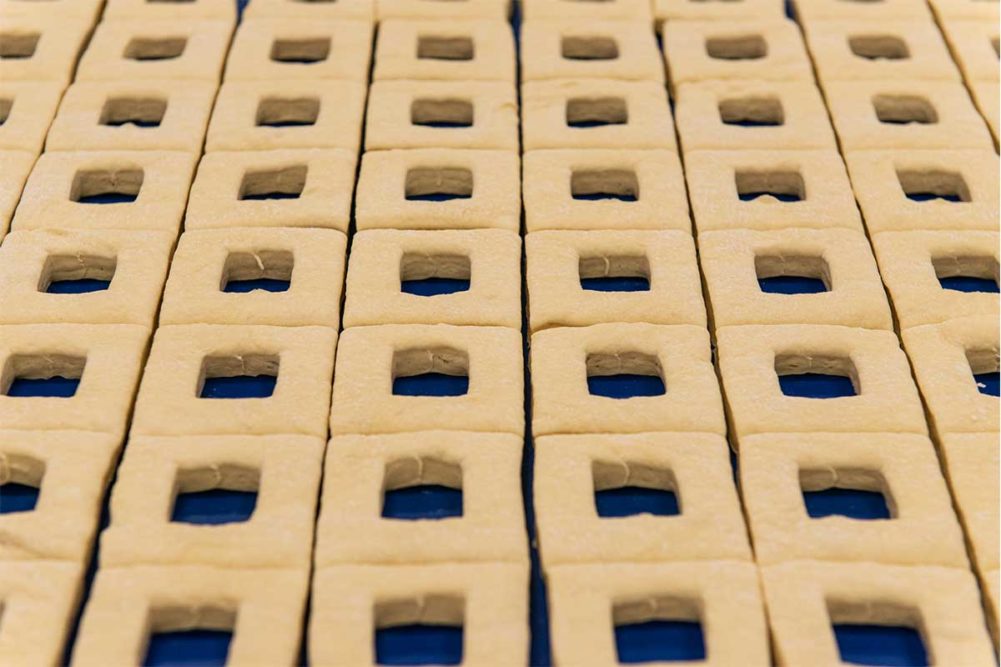

For its square donuts, the sheet slowly moves through a cross roller, flour duster and a gauge reduction station before a series of cutters slice it into eight strips followed by guillotining the pieces into the proper length. After cutting, an operator will manually pick out the square donut holes before they are transferred to a Belshaw line for proofing, frying and glazing.

By the way, UDF’s donut holes aren’t square.

“We take our squares that come out of the center of a donut and run them through the proofer and the fryer, and they come out round,” Mr. Lopez said. “You just can’t make a square donut hole. It’s too small to retain its shape.”

Afterward, proofing takes about 55 minutes in the four-stage flourless flight proofer that holds about 6,400 donuts at a time. After docking to release gases, rows of six donuts enter the fryer, flipping halfway through the 1-minute process. Depending on the production schedule, the frying process runs for up to six hours daily.

During the first part of the run, freshly fried Bismarks, Long Johns and square donuts are then trayed, racked and cool for 1.5 hours prior to icing and filling. Then the bakery turns on the automatic glazing system for the remaining yeast-raised donuts, cinnamon rolls and kettle donuts.

UDF makes its own icing and chocolate ganache in Savage Bros. 300-lb kettles. Mr. Lopez said the bakery added a new depositor from Hinds Bock, a Middleby Bakery company, with positive displacement that fills donuts in half the time. The donuts are then trayed and later sorted for distribution to every store.

After a changeover, yeast-raised production wraps up with glazed cinnamon rolls, where the spice is incorporated into the mixing process as well as dusted onto the dough during makeup. Finally, the bakery slacks out frozen, laminated dough that’s fed through the Rademaker makeup line before operators skillfully twist the pieces into shape prior to proofing, frying and glazing.

In recent months, Mr. Lopez noted that the bakery added a MIWE rack oven as the first step in its initiative to add more ovens as it broadens its baked goods portfolio. A third-party vendor uses a UDF-developed formula to make gourmet cookie pucks that are baked off at the facility and individually wrapped on a semi-automated Ilapak horizontal form/fill/seal machine. Likewise, custom-formulated brownie squares are baked off, then packaged in grab-and-go twin packs.

Since the startup, UDF has focused on continuous improvements. Mr. Lopez said the bakery’s senior management team and ownership meet weekly to review sales and waste numbers as well as to evaluate the characteristics of its baked goods.

New products, he added, are presented almost weekly to review and schedule for potential test marketing. Key performance indicators from every production run are tracked on a board posted in the bakery.

Looking forward, the next expansion for the facility involves enhancing its distribution capabilities. Specifically, Mr. Lozano said, UDF plans to add an 18,000-square-foot refrigerated and dry storage facility. From here, milk, donuts and other fresh perishable foods will be distributed on 14 newly ordered 26-foot temperature-controlled trucks starting early next year.

For UDF, the production of square donuts represents a new beginning, a journey in a different direction and a shape of things to come for the manufacturing side of this family-run c-store chain.

This article is an excerpt from the August 2021 issue of Baking & Snack. To read the entire feature on United Dairy Farmers, click here.