Perhaps the hottest trend in automation involves future-proofing production lines to anticipate shifts in consumer sentiment and changes in the market.

“Flexibility, modularity, hygienic design, reducing labor and digital quality control systems are important reasons to create a production line that’s ready for the coming decades,” said Hans Besems, executive product manager, AMF Tromp, an AMF Bakery Systems brand. “Return on investment along with predictive maintenance — so hard stops are avoided and production can keep on going — are important for the continuity and profitability of a bakery.”

That’s why AMF Tromp also consults on future-proofing new lines when scaling up production.

“What kind of products, volume, variety, flexibility, digitalization, hygienic design and availability of labor are all topics we discuss and take into account designing new lines,” Mr. Besems said.

When expanding or building a new plant, bakers need to answer key questions.

“We always want to look more to the future,” said Peter Spinelli, president and general manager, Rondo North America. “How do bakers see production developing over time? What other products may they be considering so they don’t lock themselves into only today’s needs, but instead, think about how their bakeries can grow.”

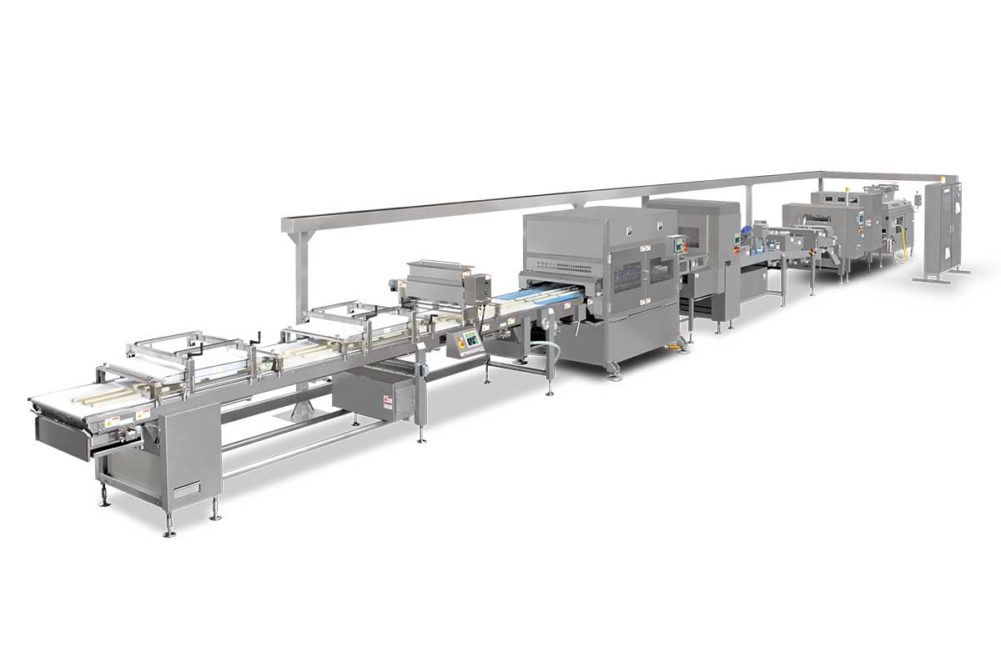

Alexander Weissbach, head of technology, product management at Rondo’s Dough-how Center, said Rondo’s philosophy is to design modularity into a sheeting line so that bakeries can easily add systems to accommodate emerging market dynamics.

“It’s not only about production capacity and going faster and faster, but also about product flexibility and creating a wider variety of products on the same line,” he said. “We can add a long moulder for creating baguettes or provide our RondoBot for producing rounded bread out of the square dough pieces on the original sheeting line.”

In recent years, Rheon introduced its rounder for making boules along with the flex V4 feeder system that adjusts the dough width at the divider to reduce scraps and improve quality. John Giacoio, vice president of sales, Rheon USA, said bakeries should incorporate a building-block approach by initially sizing and designing artisan bread lines for inevitable expansion.

“As long as bakers know how far their operations may grow, we can offer lines with increased capacity that can be tapped in the future,” he observed. “Because our lines are modular, we can add moulding or rounding capability as their product offerings grow. The key to this is having the space that is needed, so build big. It will fill up faster than you think.”

Too many times, however, bakers underestimate the amount of space needed for automating.

“Artisan production generally requires patience and time in the mixing, makeup and resting stages of the process,” said Jerry Murphy, vice president of sales, Gemini Bakery Equipment/KB Systems. “Gaining assistance with simulations of future scale-ups is key to anticipate space requirements and layout options in order to not paint the process into a corner. Using our ‘integrator experience,’ Gemini can visualize and assist artisan bakers with seeing the challenges about process, space, operational workflow and overall product quality to help mitigate many of the potential pitfalls and provide equipment and system solutions that can be expanded into the future.”

Mecatherm has developed modular ovens and compact, vertical dough handling systems with a small footprint that adapt to the process time required by the type of products made. Marie Laisne, product marketing manager, Mecatherm, pointed out the entire production line can be designed around versatility.

“Bakeries can decide to install several handling modules and use only part of them when needed,” she said. “This enables bakeries to be very flexible depending on the process time needed during proofing or cooling, for instance. On the contrary, bakers can decide to add additional modules in a later stage as business volume grows.”

For craft bakeries searching to scale up production, the latest advances in technology can be strategically used to bolster capacity without sacrificing quality and bring better breads to the broader market.

This article is an excerpt from the September 2022 issue of Baking & Snack. To read the entire feature on Artisan Bread, click here.