Pro Tip: The molecular interactions between gluten and various fiber sources are unique, leading to differences in baking quality for low-carb breads.

Low-carb bread options are trendy. 2020 research from Statista reports nearly one in five Americans are attempting to follow a low carb or no carb diet. This is coupled with increased consumer demand for products that promote healthy bacterial fermentation in the gut, which means supplementing soluble and insoluble dietary fiber.

Developing low carb bread has proved challenging, however, since the starchy component of wheat serves important roles during baking, especially gelatinization and acting as a filler in the gluten matrix. Additionally, adding fiber from different sources, such as fruit pectin (apple, citrus), hydrocolloid gums (guar, agar), inulin and others impact the way gluten develops.

When developing new low-carb products, it is important to consider how gluten develops and how different fibers interact with the gluten matrix.

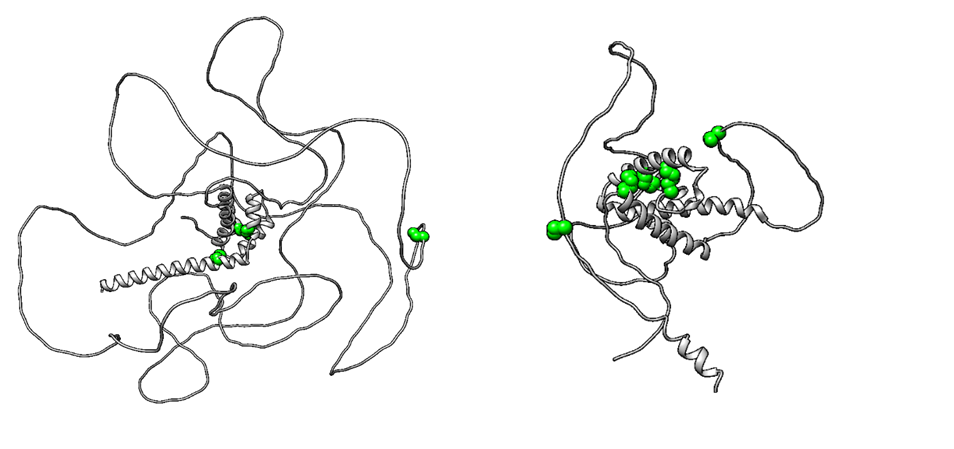

Figure 1: Protein structural models generated from AlphaFold2 highlighting the locations of Cys residues in the protein structure that are responsible for the formation of disulfide bonds (green); Left: High molecular weight glutenin; Right: Low molecular weight glutenin.

Figure 1: Protein structural models generated from AlphaFold2 highlighting the locations of Cys residues in the protein structure that are responsible for the formation of disulfide bonds (green); Left: High molecular weight glutenin; Right: Low molecular weight glutenin.Gluten forms when high molecular weight (HMW: 67-88 kDa) and low molecular weight (LMW: 32-39 kDa) glutenin are hydrated and sheared in the mixer. As the figure demonstrates, these proteins both have a core that is comprised of α-helical structures and a few disulfide bonds.

It is thought that the rest of the native protein is unstructured, which allows for rapid penetration of water into the protein, making it more flexible. Shear forces in mixing can break the existing disulfide bonds, allowing glutenin to form new disulfide bonds with other nearby glutenin molecules. These long strands serve as the skeletal structure of most baked goods.

Gliadin, the other major protein involved in gluten formation, interacts with these long protein strands through non-covalent forces, such as hydrogen bonding and hydrophobic interactions.

In terms of protein’s secondary structure, more hydrogen-bonded β-sheet structures appear during mixing, also contributing to dough strength. Together, the glutenin makes the dough stiffer (more elastic) and the gliadin provides more liquid-like characteristics (viscous); thus, the dough is viscoelastic. If fiber is present, however, it can impact the formation of this network.

Fiber from a variety of sources, including fruits, vegetables, hydrocolloids and cereal grains have been studied to evaluate how they interact with gluten during hydration and mixing.

In nearly all cases, there is a decrease in disulfide bonding as the result of fiber addition. This is primarily because the fiber absorbs water from the system, so the gluten stays more rigid and does form as many bonds. The amount of protein is also diluted. This makes hydration critical when working in high-fiber formulations.

Additionally, it has been found that fiber from a variety of sources decreases the β-sheet content of mixed dough. This can be from a lack of hydration as well, but many fibers form hydrogen bonds with gluten, competing with the protein to form these same bonds and reducing β-sheet content.

Interestingly, it was found that cranberry fiber increased the proportion of β-sheets, which may be useful in developing stiffer doughs.

It is difficult to generalize findings across fiber, though pectin from apples and citrus pomace both had somewhat less of an impact on gluten’s structure (disulfide bonding and secondary structure) than other fibers. This is especially true if the fibers have been pre-treated to reduce their molecular weight, and there is a general trend for lower molecular weight fibers to be less detrimental to gluten development.

Another factor to consider is the degree of crystallinity, measured through x-ray diffraction. More crystalline fibers will require more energy and water to unfold and gelatinize during baking, which impacts baking time and temperature in low-carb products.

While creating low-carb bread is still a difficult task, an understanding of how fibers interact with gluten in these products is a great place to start in creating bread that consumers will love.

Harrison Helmick is a PhD candidate at Purdue University. Connect on LinkedIn and see his other baking tips at BakeSci.com.

His research is conducted with the support of Jozef Kokini, Andrea Liceaga, and Arun Bhunia.