Pro Tip: Mycoprotein — the protein rich biomass made from fermenting fungi mycelium — is showing promise in functional applications such as emulsification and increasing bread volume while also being nutritionally dense and sustainable.

Mycoprotein, also sometimes referred to as mushroom protein, is a protein-rich material that is fermented in bioreactors, much like the production of many enzymes used in the baking industry.

The most well-known brand of mycoprotein, Quorn, was first produced in the 1960s. Its popularity has recently increased from consumers demanding sustainable foods.

Production processes of mycoprotein offer particularly good sustainability potential, since the mushroom mycelium can be grown on several industrial co-products, including current waste streams of juice production, brewers spent grains and even stale bread.

Each fungal strain prefers different growing conditions and nutrients, which can lead to drastic differences in terms of mycoprotein functionality. Therefore, it is important to become familiar with specific products to achieve consistency when using mycoprotein.

Here, two different strains will be discussed with applications including bread production and emulsification.

The most common strain of mycoprotein, Fusarium venenatum, has been approved by the Food and Drug Administration (FDA) and is used in many commercially available alternative meat products.

When produced in continuous flow bioreactors, the resulting product is approximately 50% protein; its amino acid profile and digestibility are comparable to milk. The products also contain high levels of fiber and appreciable omega-3 fatty acids, leading to several potential health claims when using these products.

Scientists have identified cerato-platanin proteins, which are associated with hyphae growth, to be relatively abundant. These proteins are strong emulsifiers, leading to emulsions with as good or better properties as milk proteins in some cases.

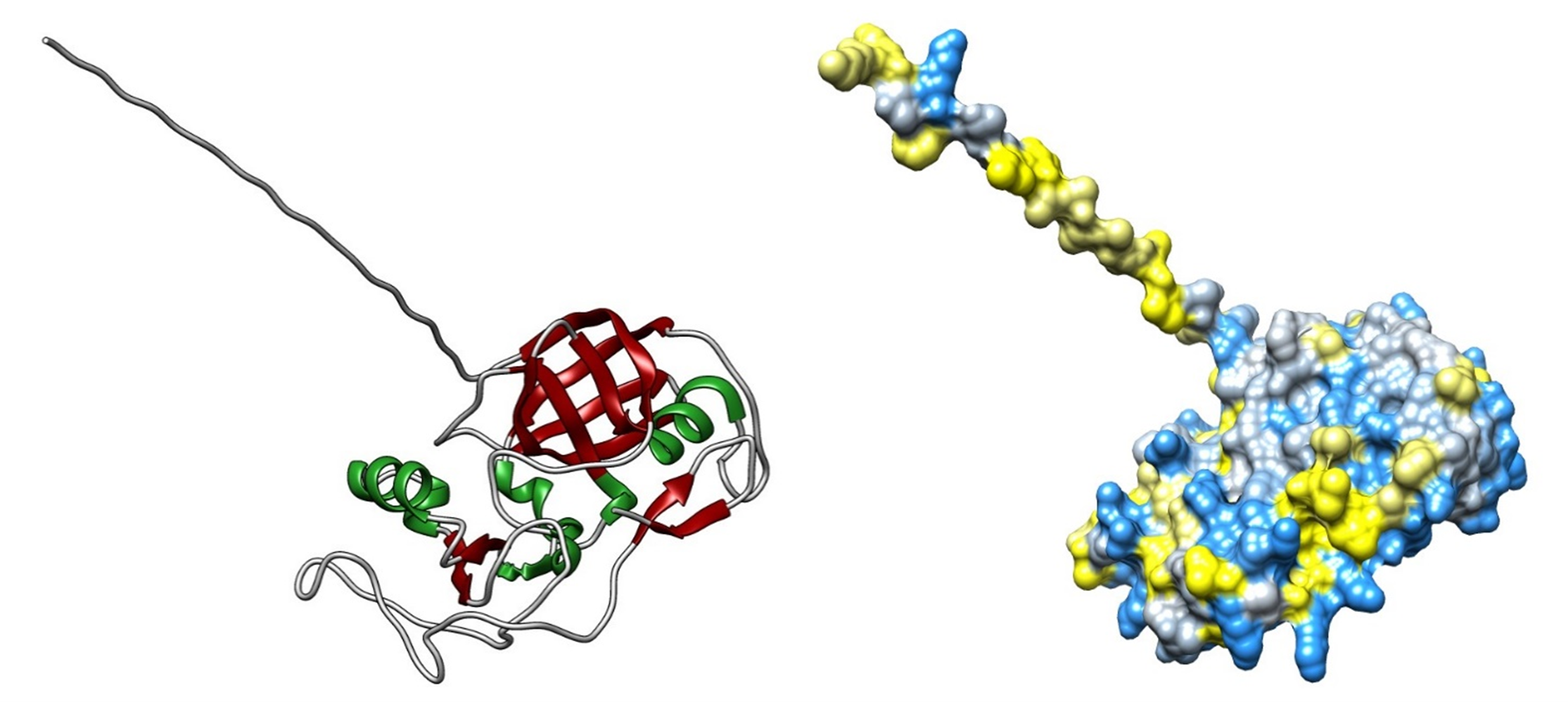

It is thought their emulsification abilities are due to their molecular structure, where a long hydrophobic random coil protrudes from a relatively more hydrophilic region of the protein.

This may help in the production of stable emulsified dough systems, such as cake and muffin batter, while also increasing their nutrient profiles in terms of added fiber and protein.

Figure 1: Protein model of cerato-platnin, an emulsifying protein found in mycoprotein. Left shows the secondary structure where red arrows are β-strands, green indicates α-helices and grey are random coils. Right is the same protein with a surface applied colored by hydrophobicity, where yellow indicates more hydrophobic surfaces and blue indicates more hydrophilic.

Other mycoprotein work has studied the Cordyceps militaris fungal strain grown on chickpeas and used the resulting products in bread. It was found that bread with 5% added mycoprotein had higher protein levels and lower carbohydrate levels.

In addition, the bread’s volume increased, which was attributed to amylase activity in the mycoprotein helping the yeast hydrolyze starch, providing more food for the yeast during fermentation. Loaf volume could also increase due to better emulsion stability in the dough, since well-emulsified dough has better stability during proofing.

In sensory evaluation, the mycoprotein-enriched breads were rated more favorably than bread with no supplementation. While mycoprotein production is still scaling up, there are commercially available strands that are worth exploring for product development in the baking industry, and it might even help upcycle stale bread and crumbs from bakeries.

Harrison Helmick is a PhD candidate at Purdue University. Connect on LinkedIn and see his other baking tips at BakeSci.com.

His research is conducted with the support of Jozef Kokini, Andrea Liceaga, and Arun Bhunia.