Advances in vision systems and end-of-arm technology (EOAT) combined with artificial intelligence (AI) are taking robotics to a whole new level.

“Vision-guided robotic applications leverage 2D and 3D cameras as an enabling technology that enhances the benefits of robotics in industrial processes,” said Harley Green, director of strategic accounts at Soft Robotics. “This also increases flexibility, reduces mechanical fixturing, facilitates quicker part changeover and ultimately reduces costs.”

Moreover, Felix Pang, sales engineer, ABI Ltd., noted that 2D and 3D cameras present different information to the users but do not provide the full picture.

“At ABI, latest developments have been made to integrate multiple types of vision sources into a single platform to allow the users access to a much more comprehensive understanding of their product,” he said. “Additionally, by combining the vision platform with artificial intelligence and machine learning algorithms, our vision system is able to detect and distinguish products with greater accuracy and more in-depth analysis.”

Craig Souser, president and chief executive officer, JLS Automation, suggested that vision systems are advancing, in many ways, faster than pure robotic technology.

“They are now incorporating AI or machine learning to make them more versatile, and 3D is starting to become commonplace, allowing us to address applications that we could not previously,” he pointed out.

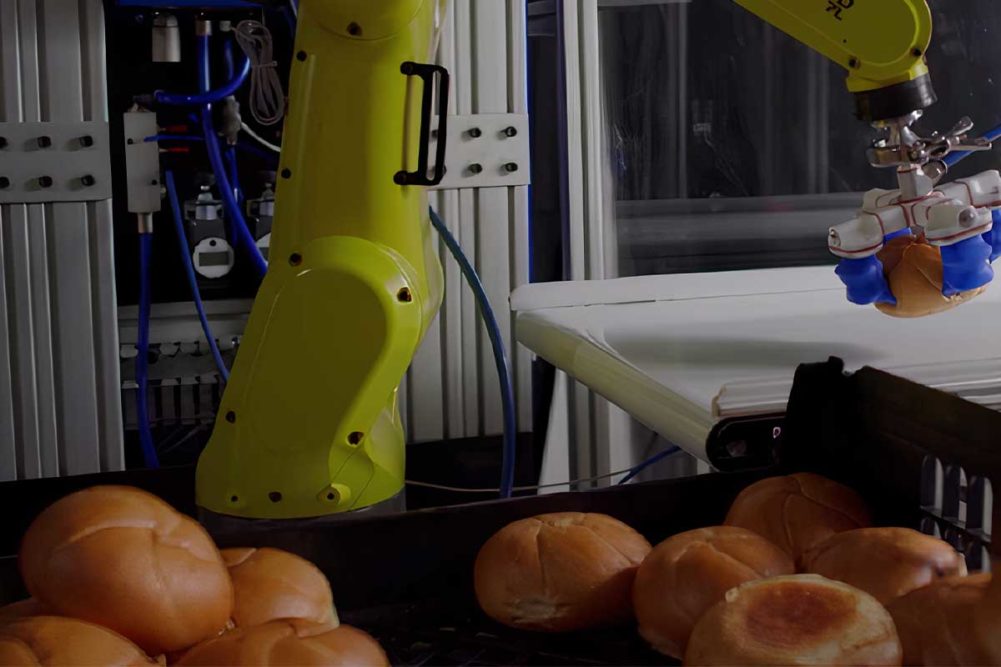

EOAT technology also has a better grasp than in the past.

“Unlike the human hand, or traditional vacuum systems, robotics with an end-of-arm tool with Soft Robotics technology can gently form around the product to lift and place product without the need for custom tooling or programming — and do so accurately without damaging product,” Mr. Green said.

This article is an excerpt from the April 2023 issue of Baking & Snack. To read the entire feature on Robotics, click here.