Production room sanitation is not as simple as pulling out a water hose. Food safety requires well-thought-out procedures that are understood and followed by the cleaning team.

“In the food production environment, we often see dry cleaning with compressed air, sweeping up heavy debris and then completing a full wet clean with sanitizers and rinse,” said David White, chief executive officer, Quantum Technical Services. “Dry cleaning minimizes water needed for cleaning and reduces the amount of solids flushed down the drain.”

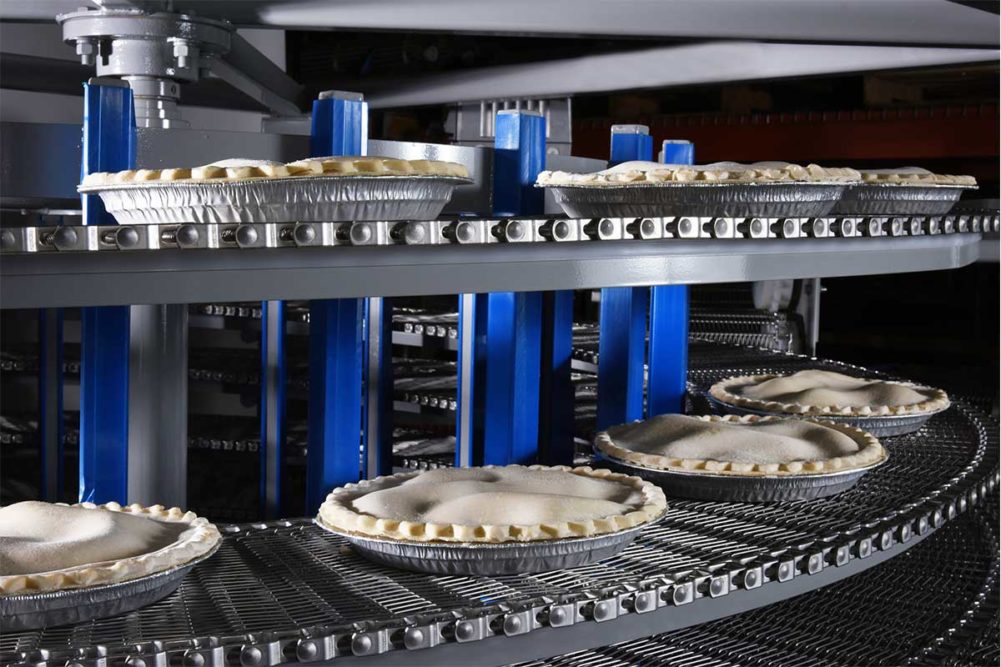

Jeremy Shall, industry team leader, bakery/snack, North America, Intralox, pointed out that wet versus dry cleaning is a complex topic. A combination of water, the correct detergent and brushing, scraping or other mechanical action will effectively remove soil, bacteria, mold and allergens from surfaces. The difficulty, however, is determining how compatible wet cleaning is with the operation.

“Bakery equipment is not always designed for wet cleaning, and when water and chemicals are introduced, equipment may degrade more quickly, causing corrosion and increased wear,” Mr. Shall said.

Likewise, the production floor needs adequate draining, and it takes time for proper drying to ensure product quality and avoid such issues as molding and compromising shelf life. Sometimes introducing water into certain parts of a bakery will create conditions that foster the growth of potentially harmful microbes.

“Water helps bacteria grow at a rapid rate, and dry cleaning may be more appropriate,” said Bryan Hobbs, service director, Ashworth Bros. “Dry cleaning, however, leaves more residual dust that can be abrasive and can be detrimental to conveying systems.”

Jonathan Lasecki, Ashworth’s director of engineering, prefers wet cleaning because it’s effective and allows bakers to minimize boiler use and compressed air that require a tremendous amount energy. He emphasized, though, that it must be done the right way.

“Wet cleaning is great, but if you don’t get all of the dried ingredients washed off, bacteria will continue to grow and you’re going to have more issues,” he explained. “Dry cleaning is good, but that’s like dusting at home. You are only moving the debris around, and not cleaning as effectively as you could, causing safety issues. You get dust on the floor that makes it slippery, or it’s contaminating your bearings, causing wear issues. It must be done correctly and efficiently.”

[Related reading: Ensure conveyors get a clean bill of health]

Following baking, wet cleaning hot conveyors can cause some high-temperature materials to swell, noted Jake Wills, conveyor project manager, Stewart Systems, a Middleby Bakery company.

While it can be effective in removing baked-on products and excess oil, the process requires more dedicated downtime for proper cleaning, rinsing and drying. Moreover, he said, sanitarians need to pay close attention to detergents to ensure they use the correct concentration to prevent damage.

During wet cleaning, Adam Erickson, project manager, Axis Automation, advised that bakers use rust-resistant, stainless-steel components along with hard-coated or anodized aluminum that doesn’t oxidize. Overall, he prefers the advantages of dry cleaning.

“Wet cleaning involves more caustics, acids and bases, which are the real culprits instead of the water itself causing issues,” he said.

Then again, Mr. Shall pointed out that dry cleaning also has challenges, especially with spreading allergens, but the process does allow for the strategic use of alternative technologies, such as steam, which some bakers may not know.

“These systems can be effective but may not be as efficient as wet cleaning,” he said.

When deciding on the best options, Mike Frazier, engineer, Axis Automation, said safety plays a factor in sanitation decisions.

He noted that dry cleaning is most often done in-place over the line. Cleaning equipment that spans a process line typically requires personnel to reach over the line from one side or the other. Wet cleaning is most often done after the equipment has been transported to a washdown area where it’s accessible from all sides.

This article is an excerpt from the February 2021 issue of Baking & Snack. To read the entire feature on conveyors, click here.