Pro Tip: Carob germ proteins can make viscoelastic dough similar to gluten; however, it tends to break down quickly at high mixing strains, which should be considered during scale-up.

Carob germ is a unique ingredient that was first shown to have viscoelastic properties similar to wheat gluten in 1935.

Despite offering a complete source of protein and boasting a non-allergenic status, carob germ is not widely utilized in the baking industry for gluten-free formulations.

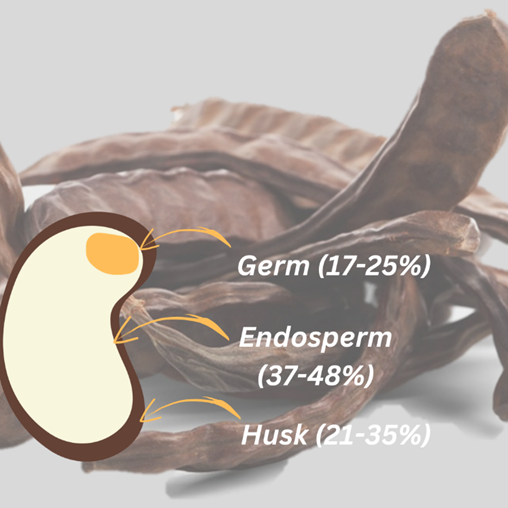

Carob germ makes up 17% to 25% of carob seeds by weight; the germ is a co-product of carob bean gum production (also called locust bean gum), which uses the endosperm of the seeds. This makes carob germ an attractive ingredient for upcycling and sustainability claims.

Once the germ is removed from the endosperm and husk, it is commonly milled into flour that is rich in protein (58% to 67%) and contains 13% to 23% carbohydrates and 6% to 9% lipids.

The proteins in carob germ flour produce stiffer emulsions with smaller droplet sizes than soy protein and wheat gluten, a property that could be useful in stabilizing gluten-free cake and muffins that rely on strong emulsification during mixing.

Before isolation, the protein in carob germ flour is comprised of 32% water soluble albumins or globulins and 68% glutenin proteins. The glutenin proteins, called caroubin, are often isolated for further evaluation; they have recently been studied for several baking properties, showing promise for gluten-free product developers.

In work investigating the Farinograph mixing properties of wheat gluten and caroubin isolates, it was found that the carob germ proteins reached the 500 Brabender Unit (BU) mark of optimal absorption after 13 minutes of mixing; the dough remained stable for an additional 23 minutes.

In contrast, wheat gluten took 35 minutes to develop under similar conditions. This showed that the caroubin proteins tend to absorb water significantly faster than wheat proteins, attributed to a lower molecular weight and greater affinity for water.

The importance of binding water was further highlighted in a comparison of soy flour, chickpea flour, pea protein isolate and carob germ in formulating gluten-free bread, which found that the carob germ dough was significantly stiffer than other protein sources and that the bound water was important for the network that formed in the carob germ doughs.

In terms of formula development, this suggests that water content should be optimized to prevent gummy doughs but still have enough water to hydrate the protein and form the viscoelastic network between caroubin proteins that can expand in proofing.

The network that forms during mixing of caroubin protein products is stabilized in part due to disulfide bonds that form between high molecular weight proteins, though the quantity of disulfide bonds is less than gluten. The caroubin network relies on significant contributions from low molecular weight proteins in the carob germ.

The combination of disulfide bonds and non-covalent interactions leads to relatively stable doughs from carob germ protein when the mixing conditions are mild, with stability times comparative to wheat dough in farinograph mixing.

However, at high levels of shear, characterized by large amplitude oscillatory shear (LAOS) measurements, it was shown that carob germ proteins broke down faster and more completely than wheat gluten.

Industrial mixers are high-shear and high-strain pieces of equipment, so mixing speeds should be closely monitored and kept as low as possible to not over mix carob germ protein doughs. The weak matrix is susceptible to breakdown from the application of industrial levels of strain.

Pre-hydrating the carob germ and adding it to the dough later in the mixing process may help with breakdown in mixing. Given the fast water absorption and network development, mixing times can be kept shorter in carob germ doughs.

In sensory experiments comparing gluten-free products, carob germ formulations were denser and chewier than chickpea, pea and soy but did not perform significantly differently in terms of flavor, showing some promise for future product development.

Harrison Helmick is a PhD candidate at Purdue University. You can connect with him on LinkedIn.

His research is conducted with the support of Jozef Kokini, Andrea Liceaga, and Arun Bhunia.