Today’s bakeries are more accepting of technologies to automate processes and improve production consistency. Consumer demands, rising ingredient prices and operating costs, a growing and fiercely competitive landscape, and other challenges of recent years have been key drivers for the push to integrate technologies that streamline production methods and help manufacturers make data-driven decisions.

If your bakery is beginning down the path toward the “bakery of the future,” here are some examples of where bakeries are finding success.

Vision Inspection Throughout the Baking Process for Better Process Control and Waste Reduction

In the last few decades, vision inspection technologies have emerged as a valuable and trustworthy method for bakeries to rapidly assess products for attributes like size, shape, color, and other features important to the product type and brand. Many companies have successfully integrated these systems as a final checkpoint to ensure finished baked products meet visual tolerances, helping streamline a manual, operator-dependent process.

Yet quality and waste are the two sides of the same coin. A higher quality standard without process improvement by default will produce more rejects and waste.

As vision inspection technology has advanced, more companies have begun finding new uses at various points of the production process before baking occurs to improve quality and reduce waste at the same time. Bakers can now go upstream in the process and more clearly understand where the quality breakdown is, then fix it before the product is produced at the end of the line.

Vision Process Control (VPC) is a great tool that bakers can utilize to investigate and improve the process to ensure quality along the production line. VPC is a vision inspection system that can be mounted directly over the production line in various locations, such as after the proofer, before and after the oven, after the cooler/freezer, and before packaging. It inspects 100% of products running on the belt for size, shape, color, and other defects. VPC is non-intrusive without modifying the production flow and provides full-quality data for bakers to understand where the quality breakdown is in their process.

In contrast to the earlier-mentioned Final Product Inspection (FPI) systems that inspect products for visual properties before packaging, VPC systems help close the loop on quality by providing the operator insights on the production process itself.

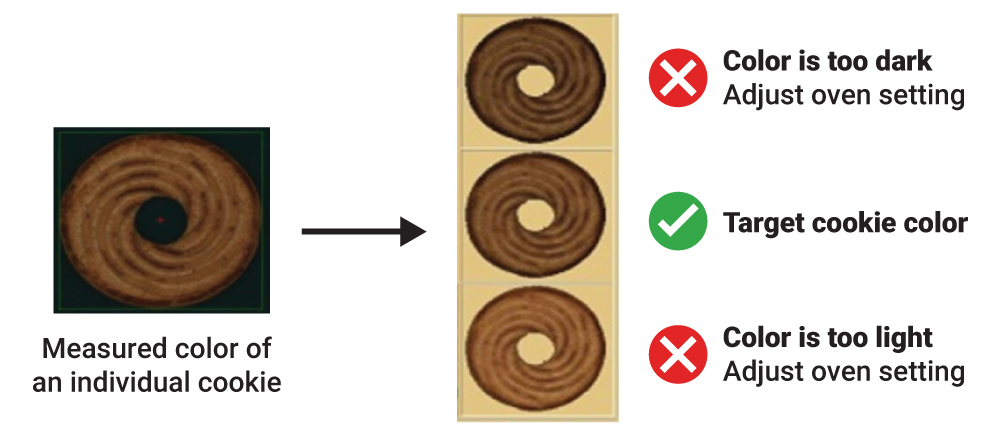

The flexibility of vision inspection technology makes it an attractive option to help baking companies control quality across many different baked product types. For instance, as shown in Figure 1, a cookie/biscuit manufacturer may prioritize the overall color and uniformity of their final products, while a bread bakery may value insights directly after dough shaping, through proofing, and after cooling to verify their production decisions.

Figure 1. Vision Process Control (VPC) technology provides objective feedback to the oven operator for the target color in a cookie line. (©KPM Analytics, Inc.)

These applications can help determine if adjustments are needed on different production lines – or even different lanes within the same line – enabling 100% inspection of products, helping reduce errors and waste before they become more significant problems.

Verifying a Balanced Oven Made Simply

Oven balancing is a process control challenge for many producers of baked goods. Many industrial-sized ovens contain multiple overhead heating elements that bake the raw dough in sections. As with all machinery, these elements can begin to run too hot or too cool over time. It is up to the operator to identify these variations and take corrective action to reduce waste and downtime.

A baked product’s composition changes as it advances from mixing, shaping, proofing, and other steps before baking. The data acquired during the analysis of raw ingredients or routine grab samples at various stages do not always result in the ideal final product. For example, a product exits the oven, appearing underbaked or possibly burnt. In that case, the operator may erroneously blame their oven settings when it may be that the moisture of the raw dough is out of specification.

Therefore, having a method to monitor moisture and fat content at critical stages in production allows companies to achieve end-to-end control, helping reduce waste, maintain ideal product standards, improve operational efficiency, and manage energy costs. In-process near-infrared (NIR) technology helps achieve this quality assurance need.

Figure 2. The Guardian-HD sensor depicted here scans the entire width of crackers exiting the oven, helping operators balance their ovens and produce consistent products. As shown on the display, this moisture reading detects an excessively dry region on the belt, indicating a section of the range is running too hot. (©KPM Analytics, Inc.)

Some baking companies have taken the extra step to include in-process NIR analysis to analyze product moisture and fat before and after the oven exit. The Guardian-HD system shown in Figure 2 enables this unique application to scan the entire belt width to help operators make data-driven decisions that save costs and reduce waste.

Bakers are Taking More Control in Flour Specification/Quality Control Processes

Historically, the miller’s primary responsibility is to adjust flour formulations and meet the specifications needed by the baker, making them a gatekeeper of quality control. However, the baker best knows their specific process, formula, and experience to produce products at their highest standards.

By working closely with their millers and technology at their aid, bakers can establish their own flour specifications for their unique products by objectively linking product quality and flour performance. This combined effort, in turn, leads to improved product consistency, reduced waste, and fewer production challenges.

Take Wooden Bakery, for example. Headquartered in Lebanon, Wooden Bakery has endured its challenges in recent years. And now, with the Russian/Ukraine conflict, two of the leading exporters of wheat to the region, Wooden Bakery continues to adapt its methods to produce top-quality products consistently.

Some time ago – before the current struggles impacting flour availability – Wooden Bakery used Mixolab 2, a universal dough characterizer, to audit their miller's specification for flour quality.

It is not uncommon for a delivery of flour to arrive out-of-spec occasionally. However, there was a particular period when one of Wooden Bakery's millers frequently provided flour outside of desired specifications. Over time, this began to take a toll on the company's productivity.

The quality team at Wooden Bakery saw an opportunity to improve communication with their millers with the help of Mixolab 2. They showed their millers how to assess flour qualities for specific products with the dough characterizer. Since they were one of the miller's largest customers, they convinced them to invest in a Mixolab 2. Given the volume of flour they purchased from them, the miller was able to pay for their system in a short time.

Now, the miller includes a datasheet of values from their instrument, which Wooden Bakery can use to audit against their incoming flour analysis. Through this interaction, Wooden Bakery and their miller can speak a common "language" of quality, which has dramatically helped their productivity.

Think Synergy, Not an Individual Solution, when Selecting a Technology Partner

Every bakery is unique, meaning there is no one-solution-fits-all when modernizing or streamlining specific baking processes. There is value in working with a partner who realizes this, too, and will take the time to listen and craft a unique action plan. It helps if the technology partner presents the baker with a complete array of quality assurance solutions and explains how the different technologies can synergize to help bakeries succeed.

KPM Analytics is unique in this aspect – by listening to our customers and collaborating closely through the process, we help bakeries incrementally improve their operations through various technologies and close the loop on quality control.

If you plan on attending IBA 2023 in Germany, stop by the KPM Analytics Booth C1/320 to meet with our team of experts, who are ready to help you achieve the “bakery of the future.”