A recent GlobalData report on the Health and Wellness Megatrend1 highlighted a shift towards how it is influencing consumer purchasing decisions. Some 65% of global consumers were always or often influenced by the impact a product or service has on their health and wellbeing in 2022 – a statistic manufacturers should not ignore.

The vision of a healthier lifestyle is now the core driver – a fact that is supported by governments looking to improve the health of their nations. Increasingly, snacks manufacturers are being encouraged – through legislation - to improve the nutritional credentials of their products, as well as to make labelling clearer to enable consumers to make informed decisions.

How can companies like TNA help?

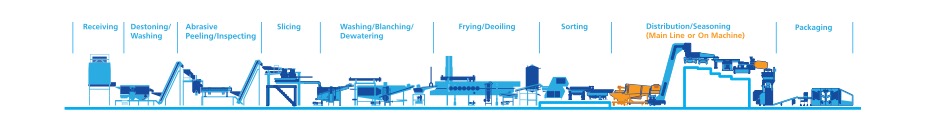

Recipes, combined with processes, determine the nutritional value of a product, and here a complete solutions partner such as TNA can add significant value by taking a holistic view of a snacks production line. Here, we will outline three elements that are critical to consider in a complete snacks line solution.

A diagram of a complete snack line solution from TNA

A diagram of a complete snack line solution from TNASource: © TNA Solutions

Frying

Frying is often associated with high fat, high salt foods like potato chips and French fries, which go against the image of perceived healthy foods. However, by deploying the right processing equipment it is possible to control oil quality during the frying process and to open up the possibility of using ‘healthier’ oils to give products a more attractive nutritional profile. Selecting a high-quality, high-stability frying oil can help minimize and even remove trans fats entirely, and there are the additional benefits of prolonged shelf life and superior taste. These elements translate well to on-pack messaging and help to distance processed foods from the stigma surrounding products with high levels of unhealthy fat content.

Frying technologies have seen significant advancements in recent years, with innovations designed to enhance the quality of fried products, improve energy efficiency, and uphold food safety standards. One such example is the TNA vac-pro® 3, a continuous vacuum fryer which fries products at lower temperatures, reducing oil absorption and lessening acrylamide formation. The result is healthier snacks with authentic colours and textures. Furthermore, TNA’s patented de-oiling unit assists in creating low-fat products, aligning with the health-conscious consumer trend.

Seasoning

Seasoning is a vital process for health and wellness in snacks manufacturing, as this is where most added salt or sugar content is incorporated. Reducing and controlling sugar and salt levels in products can be easily achieved through accurate processing equipment, enabling tight nutritional targets to be met, and reducing food waste and changeover times.

The freedom to adapt and exercise precise recipe control is vital to ensuring flexible and efficient operating practices. For TNA, its latest on-machine seasoning solutions feature independent scarf feeders and separate tumble drums to accommodate alternative product varieties on a single production line. This more automated, recipe-driven approach means manufacturers can respond quickly to demand for products with a lower salt and fat content.

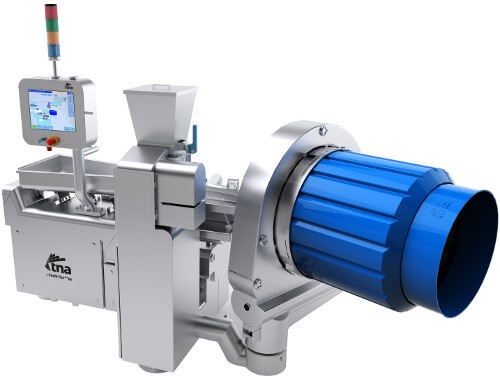

The TNA intelli-flav® OMS 5.1 is the next-generation on-machine seasoning system that provides both powder flavouring and liquid oil in a single drum. It ensures consistent and precise seasoning coverage for a variety of snacks, including fried, puffed, and baked products. The system was created in response to customers' demand for greater control over seasoning, a factor that significantly affects input costs, waste costs, consumer satisfaction, and repeat purchases. This advanced OMS system delivers precision and control, as well as aiding the reduction of food waste - an essential aspect of a sustainability strategy. By weighing raw materials and utilizing intelligent control and monitoring software, the system applies the precise amount of seasoning or oil specified by the pre-set recipe. This efficiency minimizes raw material waste and ensures consistently seasoned products. TNA intelli-flav® OMS 5.1

TNA intelli-flav® OMS 5.1Caption: © TNA Solutions

Line monitoring data

Clean labelling and traceability are closely connected to health in the minds of consumers, and transparency surrounding the manufacturing process from brands can build trust in their products. Online monitoring systems and smart equipment operating systems can provide this invaluable insight, with intelligent, accurate and customizable digital data collection systems helping brands to address shoppers’ anxieties with concrete insights at every stage of the production process. In-line systems such as barcode scanners, date code assurance tools and metal detection equipment provide many possibilities. Integrated into the production line at various intervals, barcode scanners verify the correct product batch is being processed by scanning product barcodes and cross-checking them with pre-approved production schedules. Date code assurance systems then confirm that ‘use-by’ dates are printed, complete and legible on the product packaging. Then, metal detectors and x-ray equipment continuously scan for foreign bodies, pinpointing sources of contamination within the product stream. With this comprehensive oversight, manufacturers can check, scan and verify each pack to meet both the standards of consumers and regulatory bodies. By improving traceability, brands can ensure the production process is operating efficiently, at the same time helping producers to reassure consumers that their products are a safer option. Consumers perceive sustainably produced products to be ‘fresher and safer’, largely because they offer greater transparency about their ingredients sourcing and processing methods, so it is a win-win situation. In conclusion, working with a complete solutions partner like TNA helps snacks producers realize goals and exceed their expectations. Trends such as health and wellness continue to evolve, and with an in-depth understanding of the balance required to satisfy consumers and retailers, while keeping brands profitable, TNA has the capabilities and expertise to support customers from a project’s inception to its completion and beyond. Download our in-depth white paper on healthy frying in the snacks sector here.

About TNA solutions

TNA solutions is a global leader in food processing and packaging solutions, committed to helping people succeed responsibly in a changing world. With over 40 years of experience, TNA’s global team of experts have installed more than 14,000 systems in over 120 countries. The company creates and sustains solutions that help customers realize goals and exceed their expectations, with performance, responsibility, and a customer-centric approach at the core of the business. A collaborative, consultative approach ensures measurable results and lasting success, with solutions designed to evolve and perform over time. As an inclusive partner, TNA supports a growth agenda that goes beyond business, emphasizing its commitment to people, prosperity and the planet in harmony. TNA is a powerful advocate of social justice, and aims to support children in disadvantaged communities through education, healthcare, and social enterprise programs, through the humanitarian initiatives undertaken by the Nadia and Alf Taylor Foundation.

TNA solutions: feeding ambitions

Visit www.tnasolutions.com or contact tnateam@tnasolutions.com to learn more.