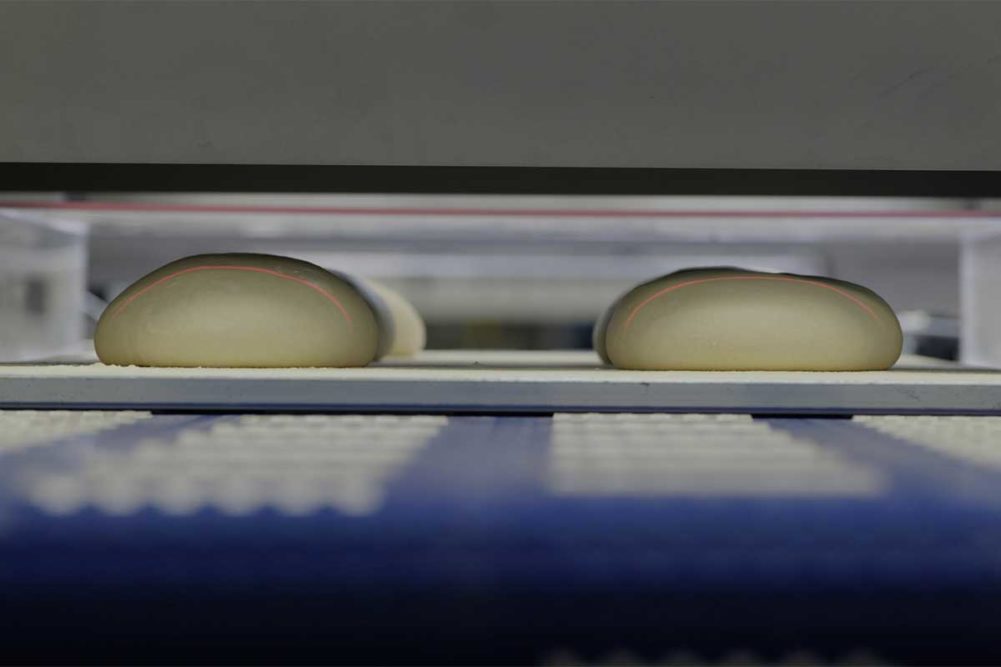

ABI Ltd.’s EYE-Q Quality Control System powered by AI can measure physical dimensions, surface topography, color, temperature and a variety of other application-specific data points at different stages of the production line. The EYE-Q system uses multiple vision sources by combining 2D and 3D sensors that can be paired with additional imaging such as thermal or colorimetry.

“Throughout the various stages of the production line, such as mixing, proofing, scoring, baking and cooling, a plethora of variables, parameters and external conditions necessitate adjustment; these all must be tightly controlled with the greatest possible precision to maximize product quality,” said Alexandre Goasmat, product manager, ABI Ltd. “The new EYE-Q Quality Control System offers easy and reliable quality control.”

The EYE-Q Quality Control System uses AI to offer insights into production issues and bottlenecks by classifying, tracking and trending defect statistics to support operators as they resolve issues rather than simply accepting or rejecting products. The high-speed system can be used for a multitude of baked goods in industrial bakeries, including delicate pastry products and desserts.

(905) 738-6070 • www.abiltd.com