Freezers come in many options but deciding on a tunnel or spiral system depends on several factors, including cost, throughput need, production speeds and space available.

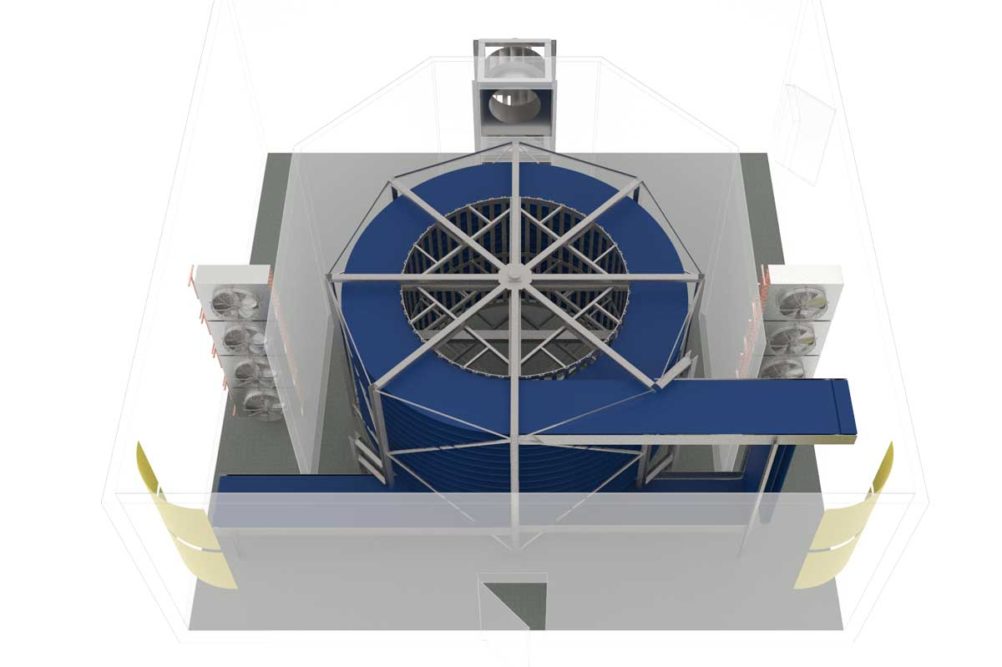

Tunnel freezers often require linear space or a greater horizontal footprint. Spirals take advantage of vertical space.

Chris Johnson, business development director, Praxair, Inc., a Linde company, noted that belt collapse, directional speed and air velocity or direction differ in tunnel and spiral freezers.

“Belt collapse results when a spiral freezer conveyor belt transitions from traveling in a straight path to traveling in a circular path,” he said.

Because the inside diameter of a spiral belt is much smaller than the outer diameter, the shorter inner belt travels at a slower speed.

“Products must be spaced appropriately to absorb this collapse and not become pressed against one another and/or deformed,” Mr. Johnson explained.

Paper, cardboard or other materials may be used to keep products separate, or the products can be placed on the belt after the collapse takes place.

Additionally, consider the directional speed for small, easy-to-freeze products. Linear tunnel freezers, for instance, can handle a high-production volume.

[Related reading: How to properly freeze pizza and baked goods]

Moreover, evaluate air velocity and direction when designing a freezer. Mr. Johnson said tunnel freezers typically blow directly down onto the items, while spirals tend to blow across products, and both systems must be designed to not interfere with the quality of the product.

Lars Soderman, sales director, Scanico, a Middleby Bakery company, said Scanico tunnel and spiral freezers rely on consistent air temperature and velocity as products travel on belt widths ranging from 16 inches up toward 60 inches for the larger tunnels.

“By regulating the belt speed, air velocity over the product, plus the internal air temperature inside the spiral chamber, the freezing process is optimized for each individual product to ensure best final product quality,” he said.

Just as in mixing and baking, freezing is all about time and temperature. Achieving consistent results involves providing consistent product and freezer temperatures and monitoring dwell time.

Switching from one product to another requires maintaining this delicate balance.

Often a simple adjustment of the temperature and dwell time should correspond to the “recipe” for the next product.

“Once the new product exits the freezer, a quality control check should be made followed by any necessary marginal adjustments to the freezer temperature and/or dwell time,” Mr. Johnson said. “If the freezer is integrated into a full-line control system, product changeover adjustments can be executed automatically.”

Another way to maximize freezer capacity involves taking full advantage of belt loading and product alignment. When switching from a 12-inch round to an 8-inch round pizza, producers need to maximize the number of the smaller 8-inch pizzas on the belt, which will improve the efficiency of the freezer.

Ricky Milner, product line support leader, Wire Belt Co. of America, pointed out that bakers need to know the product loading specifications, including pounds per square foot, to determine which type of belt is required.

“We would then ask the size of the product to determine the percentage opening needed to support the product,” Mr. Milner said.

Ashworth Bros. works closely with its freezer partners to extrapolate key information, such as product type, product load, the amount of heat transfer and moisture to be retained in the product.

[Related reading: Factors that determine freezer performance]

“That allows us to help them choose the proper belt to convey the product,” said Kenneth King, commercial support manager, Ashworth.

In addition to product variety, Intralox and its conveyor partner require information on throughput and even cleaning regimens.

“Once the basics are known, we can select a straight running or spiral platform,” said David Bogle, lead engineer, spiral platforms, Intralox. “Once the technology is known, then we can narrow down the right belting choice based on product sizes and characteristics.”

Many bakers understand the freezing conditions for their current product portfolio but often lack key information as they roll out new products.

“Intralox has a large set of freezing test equipment that we can use to create cooling curves for a product, or, even better, we have the customer come in and do freezing trials in conjunction with us to narrow down the best parameters for their products,” Mr. Bogle said.

In designing a freezer system, Mr. Milner advised to place all freezer belts entirely within the freezer.

“You do not want half of the conveyor in the freezer and the other half out of the freezer,” he said. “Doing so can cause condensation on the belt and sprockets causing a frost buildup. If the frost accumulates in the root diameter of the sprocket, the belt will skip over the sprocket teeth causing a belt slippage. If this is the case, there will need to be some sort of belt scraper on the conveyor to remove any frost buildup.”

AMF Bakery Systems’ engineers rely on a Reading Thermal Scorpion 2 to profile the performance of the Vesta spiral freezer.

“Using conveyors in a freezing room requires some design attention to avoid ice buildup and ensure the components used are specific to support the freezing temperatures,” said Bobby Martin, executive product manager, AMF.

Jonathan Lasecki, Ashworth’s director of engineering, pointed out that a plastic belt can be an insulator and affect the freezing process.

[Related reading: A freezer’s worst enemy]

“Sometimes you can trap that heat on a plastic belt between the surface of the product and the belt itself, which means you can be taking moisture and depositing it into a bag, which decreases the overall shelf life of the product,” he noted. “You don’t want to package moisture in with bread or other mold-sensitive products.”

Using lane dividers, guard edges and smooth support rails at transfer points, he added, ensures products remain aligned and separate as they freeze, which prevents commingling of products that could result in two products within one bag.

Likewise, a more open mesh belt works for fully or par-baked products, and a more closed mesh belt prevents softer products from settling into the belt.

Along with belt designs, be sure to pick the right materials. Mr. Bogle recommended acetal plastic as the go-to material for most conveyor belts.

“However, if there is a fire hazard in the area, a flame-retardant option would be the more prudent choice,” he said.

When it comes to expanding a freezer today, having all the cold, hard facts allows frozen food producers to make the best choice for their current and future new product needs.

This article is an excerpt from the June 2020 issue of Baking & Snack. To read the entire feature on freezing, click here.