Even though the Centers for Disease Control and Prevention reports that the coronavirus (COVID-19) isn’t easily transmissible through contact surfaces or food, consumers want to be 100% sure that they’re limiting their exposure. Packaging is one way they are looking to protect themselves.

“With government food safety departments, retailers and foodservice providers instituting strict new hygiene requirements in the wake of the pandemic, sanitary equipment design and maintenance has never been a more pressing concern for snack producers,” said Teri Johnson, vice-president of TNA North America.

For TNA, seal integrity is one critical component of food safety. If sugar or salt or another seasoning gets trapped in a seal, that snack bag becomes susceptible to foreign contaminants. Vacuum sealing solutions and dust and sugar extraction units protect against this.

Consumers aren’t the only people concerned about contracting the virus. Operators want to limit the risks posed to employees as well. Sanitary design and automated systems further limit the number of employees needed at the end of a line.

“Our designs allow for ease of cleaning, which allows food manufacturers to have confidence that their BluePrint Automation equipment can be appropriately cleaned and sanitized for their employees and customers,” said Mike Rebollo, southwest regional sales manager, BluePrint Automation.

COVID-19 has shined new light on the importance of automation in packaging. Manual processes create opportunities for food to become contaminated.

“Handling bakery products manually contributes to the spread of germs,” said Stephan Schuele, Syntegon Technologies. “As a result, manufacturers of baked goods are working overdrive to automatically clean and sanitize equipment and facilities in order to protect consumers and ensure the safety of their products.”

Machines built for easy cleaning provide a big advantage in this environment and solve the problem of hygienic conditions by automating manual processes.

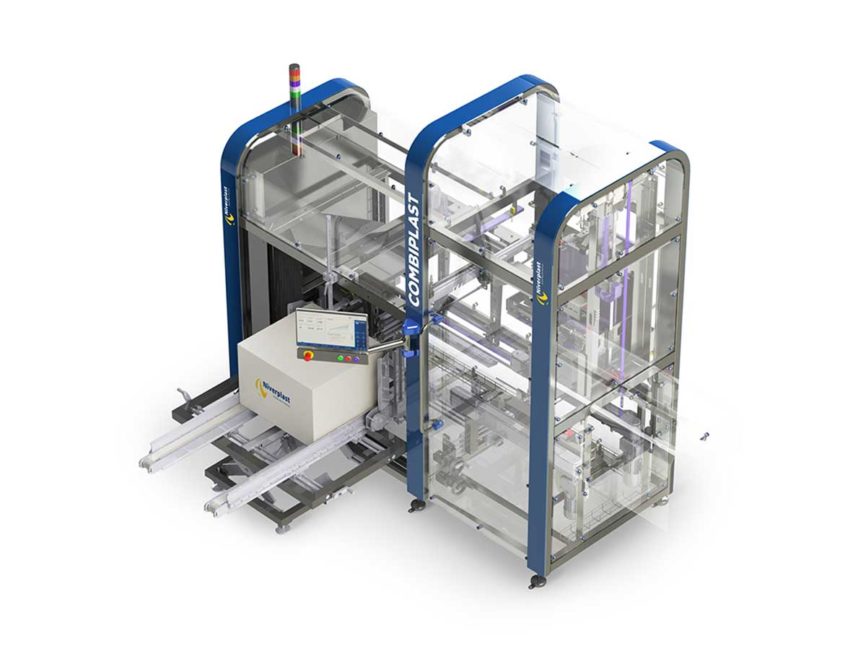

“Our fully automatic high-speed camera inspection system combined with our robotic case packing eliminates the chance for production contamination by in-plant personnel,” said Mark Finneran, United States sales representative, Niverplast.

By working with packaging equipment suppliers to customize forms of automation and provide sanitary design, manufacturers can be confident in their ability to ward off COVID-19 contamination concerns.

This article is an excerpt from the November 2020 issue of Baking & Snack. To read the entire feature on inline safety and sanitation, click here.