Bakers need to be careful in selecting an oven, or they may get burned in more ways than one. A direct-fired oven, for instance, may overbake the bread or even burn the crust if it isn’t heated correctly.

“Direct-fired heat can be a little too intense for some breads that need more time to fully bake,” noted Ondrej Nikel, PhD, director of engineering, Topos Mondial,

Then again, Phil Domenicucci, baking systems specialist, AMF Bakery Systems, pointed out the best oven for overall flexibility would be a direct-fired tunnel oven with steam, convection and equipped with a mesh belt.

“This type of oven can support baking products directly on the hearth, and with optional belt cleaning systems, production can switch to pan breads,” he explained. “The bakery can produce heavy ryes, country boules or dinner, Kaiser, rosette and long rolls directly on the hearth. The bakery can also produce pan breads and buns. This is a simple oven, both cost-effective and durable.”

For versatility, the Gemini/Werner & Pfleiderer’s Thermador, an indirect-fired tunnel oven, can provide for a fully radiant heat bake, fully convection bake or anything in between with turbulence available in all zones.

Ken Johnson, president, Gemini Bakery Equipment, explained that each turbulence section consists of evenly spaced carbon steel tubes that form the upper and lower oven heating plenums. Heated gases then flow through the plenums to create radiant heat.

Next, the hot recirculated baking chamber air passes through even spacing between the pipes that form the plenums.

Two variable-speed, recirculation blowers are mounted in each turbulence section on opposite sides of the oven. That allows the airflow to be reversible or go from top-to-bottom or bottom-to-top.

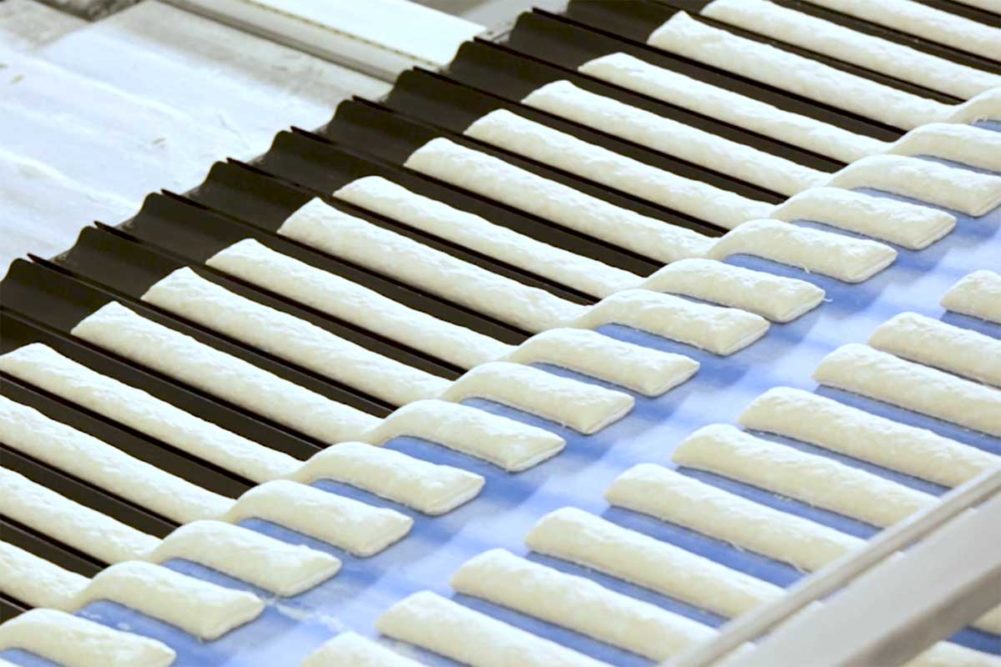

Mecatherm offers an FTM multi-deck tunnel oven for hearth or pan baking. Marie Laisne, product marketing manager, Mecatherm, said the four-deck oven features small modules with 300 square feet of baking surface, or 75 square feet per stage, that can be heated at different temperatures for a precise baking curve and to adapt to a wide variety of products.

Moreover, she said, the hearth is equipped with a bottom baking booster, which is installed in each oven deck and provides for an additional energy input to the hearth by convection. The adjustable booster provides a high degree of precision to attain the desired color and crust thickness.

Dr. Nikel suggested Topos Mondial’s J4 oven can be used to bake everything from smaller rolls and breads to larger products.

“You get the heat from the bottom and a radiant heat all around for a more consistent crust,” he said. “The combination of conductive, convective and radiant heat from the turbulence and the cyclothermic radiators allows you to balance all three components. Specifically, you can turn down the convection, but keep the radiant component there so it gives you that freedom to dial in the exact temperature that you need on most products.”

This article is an excerpt from the September 2021 issue of Baking & Snack. To read the entire feature on Ovens, click here.