New product development has reemerged as a predominant issue as retailers and foodservice chains seek to reengage budget-conscious consumers.

“Multiple flavor and color deposits for the same product cavity have been around for many years, but recently, we see this trend more broadly across the world as producers develop new product innovations,” said Rod Gregg, executive vice president of Middleby Cos., Hinds-Bock and Inline Filling Systems.

He added that more complex icing and decorating systems are replacing traditional waterfall icing operations.

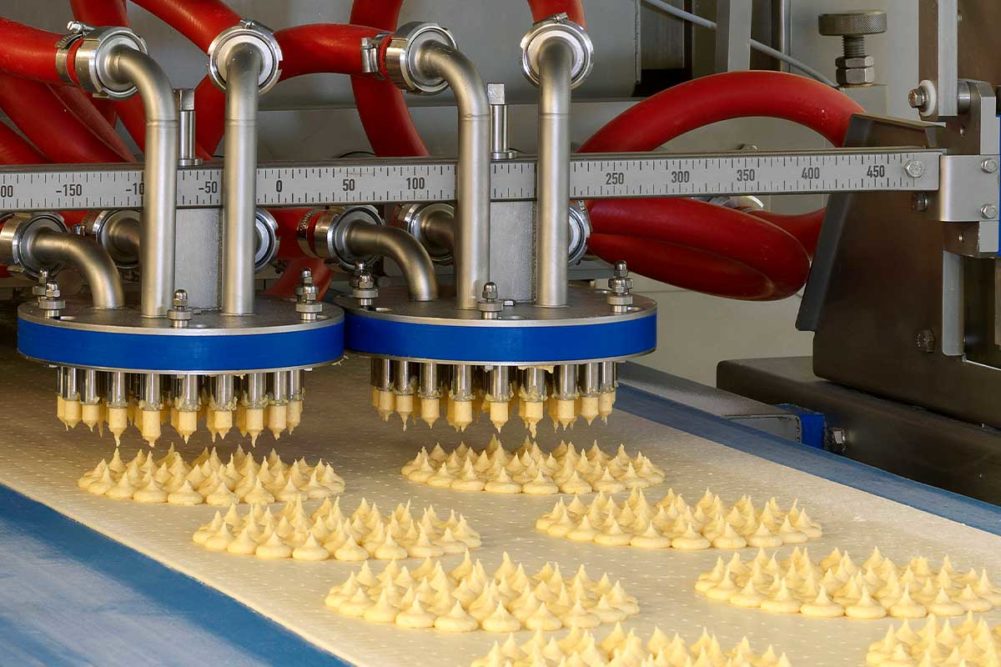

For example, Inline Filling Systems recently developed a swirled icing decoration on top of a fully baked cake.

The system relies on servo pump fillers feeding a pair of eight-across nozzle manifolds attached to two ABB robots applying a distinctive, programmable decoration pattern over an Auto-Bake Serpentine production line.

“With such a system, customers are given endless creativity to uniquely separate their products in the market,” Mr. Gregg said.

Jamie Bobyk, marketing manager, Apex Motion Control, noted the Baker-Bot is a cobot commonly paired with a depositor from other companies, but it can also run on its own with a pressurized pump.

The Deco-Bot is a self-contained robotic decorating, glazing, depositing and spraying system with a built-in conveyor and quick hookup for heated and non-heated pumps.

“Cobots are not the speed demon robotics you see on a caged line. They serve a different purpose,” he explained. “They help manufacturers with the labor crisis with a small footprint while being easy to clean and set up, and they are very safe.”

He said it’s not uncommon to see 10 to 12 cobots decorating cakes night and day on the same production line.

“This technology is coming at a very fast pace, and the early adopters will reap the benefits of having a ‘fantastic worker’ that does everything for life,” Mr. Bobyk observed.

Rademaker will display a new high-speed depositor at iba in Germany. The system enables discontinuous and continuous depositing of liquid and semi-liquid fillings, such as jelly, jams and pastes, for its croissant lines.

Nick Magistrelli, vice president of sales, Rademaker USA, said the new depositor takes up less space and has a low-level hopper for ease of filling and is simpler to clean with fewer parts.

Rademaker also offers the Monho Pump depositor for spot, discontinuous strips or continuous filling strips.

Mr. Magistrelli noted this system has a high-depositing accuracy due to the individual volume control per nozzle. The auger and mohno pump combine to deposit materials that include large pieces such as vegetables and fruit.

In addition, the Rademaker Piston Depositor is designed for spot depositing of fruit, cake batters or vegetable and meat fillings in single or multiple lanes and onto a dough sheet or into pans, plastic containers or cups.

The company’s Gearwheel Depositor comes with its set of frequency-controlled gearwheels to ensure an even, consistent flow of material with a wide range of non-particle fillings, Mr. Magistrelli said.

This article is an excerpt from the July 2023 issue of Baking & Snack. To read the entire feature on Depositing, Icing, Glazing, click here.