In the snack category, flexibility is the name of the game when it comes to processing.

“Innovation is key in the snack market, so snack makers need flexible equipment to make different varieties of snacks or even completely new products without the need for capital expenditures,” said José Coelho, president, Clextral USA. “Extruders offer this flexibility, combined with versatility to run different products on the same production line, giving processors the ability to make new products or line extensions, and quickly scale to full production.”

This is especially true for smaller snack manufacturers, who are often those working with the latest, trendiest ingredients and developing new product lines all the time hoping to break through the noise of mainstream producers.

“We see lots of activity with smaller producers who want to expand their product lines,” said John McIsaac, vice president of strategic business development, Reiser. “Our challenge is to make their machinery multipurpose. The same machine that forms and portions a high protein cookie must also be able to produce bars or fill tubs. Bakers can add our new tunnel rounders to also produce bite-size balls of product.”

The flexibility of twin-screw extruders make them well-suited for direct expanded snacks made with alternative ingredients, Mike Shaw, sales account manager, snacks/cereals, Bühler Inc., noted, especially as those products begin to overlap into new formats as well.

“The market trend to create hybrid products between snacks and crackers is also well-suited for the extrusion platform due to the wide range of possible process parameter adjustments and ancillary set-up,” he said. “The screw pushout device on Bühler twin-screw extruders ensures that changeover from shutdowns is as fast as possible.”

When it comes to using the latest ingredients, much of the flexibility that aids innovation also addresses some of the challenges that come with alternative bases. Extruders designed with flexibility have the capability to offer a precise level of control over parameters.

“When working with different raw materials and blends, you need equipment with the ability to generate the precise level of thermo-mechanical cooking to achieve the desired snack structure and product density,” Mr. Coehlo said. “These two elements are linked as they dictate the mouthfeel and crunchiness level. … The twin-screw extruder is a very versatile processing tool with almost unlimited parameter adjustments, and we rely on our expertise to find the right combination to reach our customers’ product goals.”

Christian Hüttner, process engineer, food extrusion, Coperion GmbH, pointed out, alternative snack ingredients require different levels of mechanical energy and screw speeds in order to process through the extruder correctly. Being able to adjust to those needs quickly is critical for snack manufacturers to extrude a snack piece that will be the proper weight and texture. Coperion’s ZSK Mv Plus Food Extruder can incorporate different capabilities to adapt.

“The addition of steam directly into the extruder’s process section as well as the possibility of high screw speeds allows the extruder to produce all the necessary energy so that no preconditioner is needed,” he said. “Intensive degassing possibilities help get rid of excess moisture so that even raw materials with a high moisture content can be processed.”

The ZSK Food Extruder can be individually configured to meet a snack’s processing challenges due to its modular design and the combination of free-screw volume, screw speed and torque, Ms. Hüttner explained.

In addition to adjusting to a snack’s different processing parameters, the machine itself needs to be able to swap out tooling, pre-feeders and other accessories quickly and easily to enable flexible processing.

“Coperion equips the ZSK Food Extruder with numerous features that speed up changeovers of recipes and ingredients,” Mr. Hüttner said. “Feed hoppers, degassing domes and atmospheric ventings are equipped with quick-release clamps.”

Even a co-extruder with its added complexity needs to be able to make a quick change. Rheon designed its co-extruders to feature five main assemblies that can be added or removed from the machine in just a few minutes.

“These assemblies are the only parts of the machine that come in contact with the food product, so cleaning of the main machine body is not necessary during a changeover,” said John Giacoio, vice president, sales and marketing, Rheon USA. “These assemblies need to be washed and reassembled, but we can also offer duplicate assemblies that can be used on the machine while the other parts are being cleaned.”

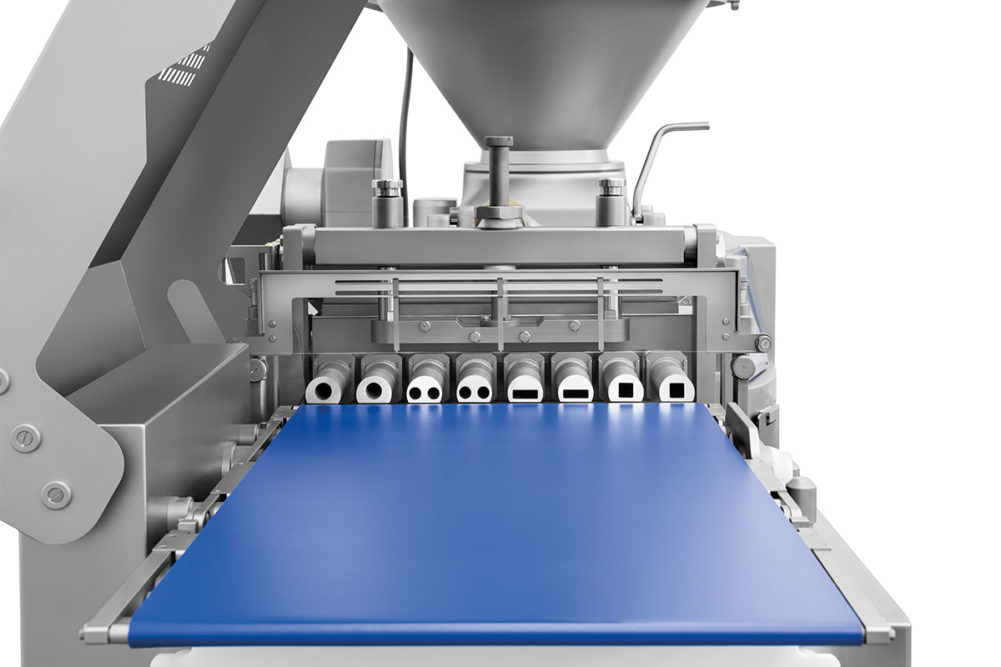

When it comes to innovating new products, Handtmann features real-time 3D shape design through its control panel. This feature allows snack manufacturers to set and test shapes immediately and then quickly change and test the next iteration. The Handtmann VF can quickly change configurations for different lanes and attachments as well as a variety of dough viscosities.

“The flexibility and rapid set up of Handtmann coextrusion solutions also offers new product development opportunities that allow simplified R&D and high-volume production with very accurate outer and inner coextruded weights that dramatically reduce giveaway,” explained Paul W. Hill, national bakery sales manager, Handtmann Canada.

Reiser aims to design its changeovers to be as tool-less as possible, and for those smaller manufacturers, they’ve added an XY Table so operators can automatically load pans full of product with the click of a footswitch.

Nico Roesler, North American pretzel and snack equipment sales manager, Reading Bakery Systems (RBS), noted that RBS’s low-pressure extruder has historically been one of the company’s most dynamic pieces of equipment.

“Whether it’s gluten-free or wheat-based, it’s the same general process,” he said. “Its flexible design features tool-free disassembly and the die and compression head are easily removeable.”

Flexibility doesn’t end after processing. The seasoning side of production often needs to be the most flexible of all, with new flavors providing the fastest way for snack manufacturers to add new products. For seasoning systems, cross-contamination is one of the biggest challenges during changeovers.

“Additional time is generally added to clean the line and reduce the chances of these occurrences,” said Josh Hughes, group marketing coordinator, Burford Corp.

Burford designed its FD2040 Sanitary Duster to be easily disassembled and cleaned to reduce the risk of cross-contamination. The hopper’s back plate, agitating and dispensing mechanisms as well as other components have all been designed with tool-less removal for efficiency.

To prevent cross-contamination, TNA designed its intelli-flav OMS 5.1 to meet IP65 (NEMA4) specifications for wet washdown environments. That means its hygienic design includes smooth food-grade stainless steel surfaces and specialized welded joints. The flavor kit is also designed for tool-less changeovers and the machine features a lightweight drum.

“These advancements in seasoning equipment streamline the changeover process, enabling snack manufacturers to respond swiftly to consumer trends and demands,” said Elwyn Cope, group solution specialist, seasoning and spraying, TNA solutions. “With efficient changeovers, manufacturers can keep up with market demands, reduce downtime and optimize production efficiency while ensuring consistent and even seasoning of their products.”

On-machine seasoning (OMS) systems, Blake Svejkovsky, general manager, product handling systems, Heat and Control, pointed out, can offer flexibility in that they do not require the entire processing line to be turned off or even throttled back during flavor changes. This keeps production moving on the same base if only changing flavor profile. OMS systems once were limited to certain products, but that’s no longer the case.

“In the past, OMS was only applicable for certain products because of issues with seasoning quality,” Mr. Svejkovsky said. “With the latest technology improvements incorporated into the FastBack Revolution Seasoning Systems’ OMS, such as AccuFlavor tumble drums, performance auto feed adjust, dynamic tumbling action and totally automated seasoning control, the seasoning quality of OMS is equal to or better than traditional systems. Now both corn- and potato-based snacks, along with other snack products are candidates for OMS.”

With innovation back and consumers seeking snacks to satisfy their every need, snack manufacturers are searching for equipment to overcome their every challenge. With flexibility and control at the forefront of equipment design, they may find just what they’re looking for from equipment suppliers.

This article is an excerpt from the August 2023 issue of Baking & Snack. To read the entire feature on Snack Processing, click here.