With high demand for snacks, even as new product development ramps up, manufacturers are still looking to keep pushing the limits of throughput.

While many production lines’ throughput is determined by the oven, when it comes to low-pressure extrusion, the limiting factor is the band cutter, said Nico Roesler, North American pretzel and snack equipment sales manager, Reading Bakery Systems (RBS).

RBS, however, has come up with a design that extends its low-pressure extruder’s capacity to make pretzel braids from 12 nozzles to 18, increasing capacity by 50% more pounds per hour.

“On a 2-meter-wide line, you can have five extruders across the belt,” Mr. Roesler said. “With the 12 nozzles per extruder, that’s 60 ropes or braids, but increase that to 18 nozzles and you’re able to load 90 ropes or braids onto the belt.”

For high-pressure extrusion, reaching high throughput rates does not have to come at the cost of product quality. By injecting steam into the process, energy is introduced to the dough efficiently, which speeds up the process.

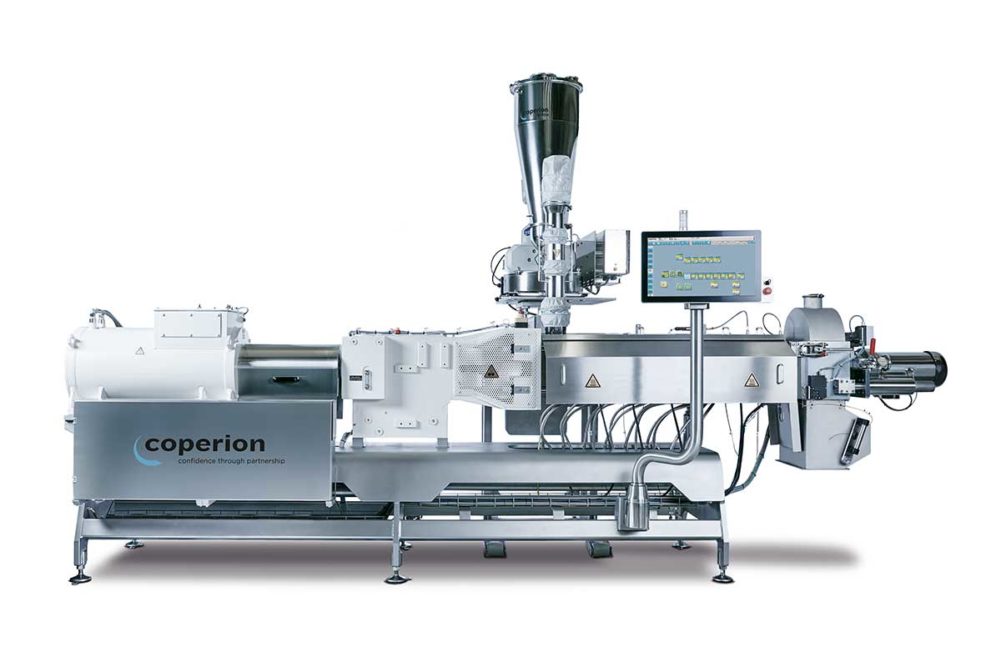

“The ZSK Food Extruder reaches very high throughput rates; at the same time, shearing and thermal stress on the raw materials are very low and the product quality is very high,” said Christian Hüttner, process engineer, food extrusion, Coperion GmbH.

Clextral designed its Evolum+ platform to reach 40% higher volume production in addition to a wider range of screw speeds and pressures.

“Clextral’s new extrusion lines offer a capacity of up to 5,000 lbs of puffed snacks using optimized floor space,” said José Coelho, president, Clextral USA. “Combined with our high volume Evolum+ dryer and flexible coating systems, snack manufacturers can readily transition from savory snacks to sweet, coated snacks and expand their product offerings using the same line.”

In order to maintain these high throughput rates, however, keeping to a preventative maintenance schedule is key.

“This piece of equipment is making you money, and when it is not producing you are not making money,” said John Giacoio, vice president, sales and marketing, Rheon USA. “If a manufacturer addresses the small issues as they present themselves it is better than to wait for the machine to completely stop working. Part of the preventative maintenance program needs to include regular and thorough cleaning. These are simple things to address, but not everyone sees the benefit until a machine stops working.”

Virtual support can also offer snack manufacturers more efficiencies when it comes to maintaining their equipment. Handtmann’s open platform HVision enables the Handtmann service team to help snack manufacturers in real-time.

“They are solving most of the routine issues quickly — providing HVISION program call backs within an hour and successful resolution of most issues within 30 minutes,” said Kelly J. Tebon, Aftermarket Business Unit Manager, Handtmann Inc.

This article is an excerpt from the August 2023 issue of Baking & Snack. To read the entire feature on Snack Processing, click here.