Bimbo Santa María started out as the birthplace of Grupo Bimbo SAB de CV, Mexico City. Today the facility is a cross-dock bakery to produce some of the company’s most in-demand SKUs in Mexico. The area that once stored finished product and served as distribution was converted into production space. Finished product is now transferred to other bakeries in the Mexico City area to be picked up for distribution throughout the region. With this shift, Santa María became a bakery dedicated to high-volume production at a high level of efficiency. The investments and line designs reflect that purpose. The bakery may be significantly smaller than its sister plant across town, Bimbo Azcapotzalco, but Bimbo Santa María still turns out 6,000 tonnes of product per month compared to Azcapotzalco’s 10,000 tonnes.

Bimbo Santa María encompasses two bakeries. One facility bakes bread while the other focuses on tortillas. The bread facility houses two automated production lines that produce small loaves and large loaves in both white and whole grain varieties.

Between the two bread and two tortilla lines, each runs three shifts, six days a week. The seventh day is saved for sanitation and maintenance. Ingredients are delivered every day by truck, and production is scheduled based on order forecasting, market demand and purchase orders from the sales team.

The Grupo Bimbo sales team is a force to be reckoned with, making fresh deliveries in Grupo Bimbo’s fleet of shining branded vehicles every day to customers throughout Mexico City. These drivers also take purchase orders from their customers that build the bakery’s production schedule. Grupo Bimbo values its reputation in the communities it serves, and the sales team is the front line in that relationship as the most visible associates. Team members are held to a code of conduct from the way they dress and present themselves to their driving capabilities and the respectful attitude they show customers and others. It is common knowledge in Mexico City that if one gets lost in the city, simply finding a Grupo Bimbo sales team member is a good strategy to finding your way again.

Back inside the bakery, Line No. 1 produces smaller loaves, both white bread and whole grain, using a liquid ferment. One mixer feeds the divider and makeup line. Line No. 2 produces Bimbo’s larger bread loaves, both in white and whole grain varieties. Two mixers supply dough to one divider that then feeds dough balls to two makeup lines. After proofing, the bread is baked in a tunnel oven and then cooled on ambient spiral coolers. Once cooled, it is sliced and packaged on packaging lines that serve both Line Nos. 1 and 2. Until palletizing, both lines are automated, a testament to the investments Bimbo has made over the years to ensure the facility is as efficient as possible.

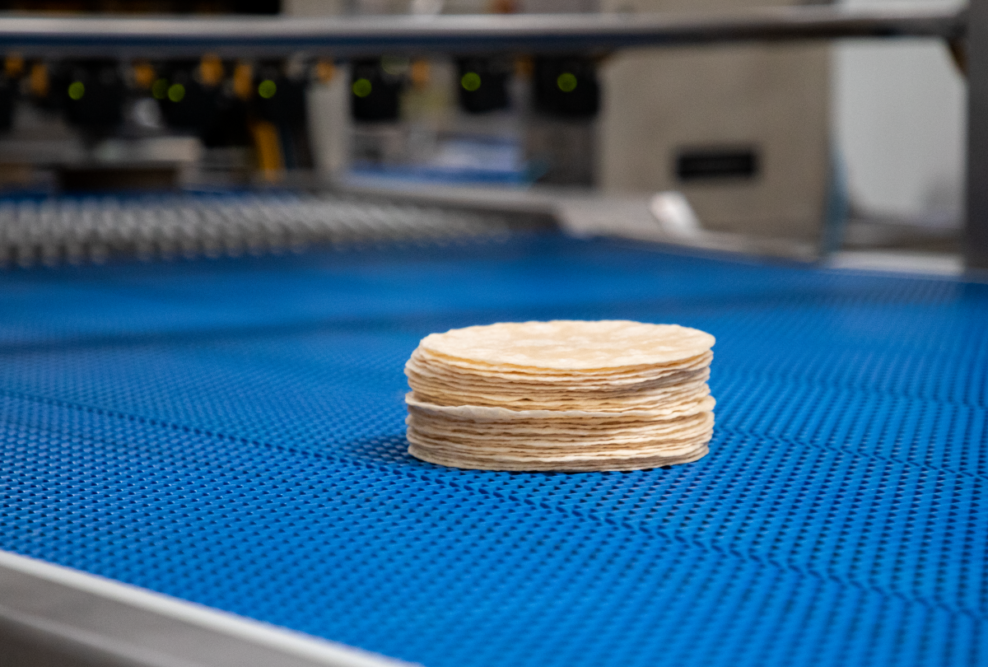

Across a narrow street in the other building is the company’s latest investment in Bimbo Santa María, two tortilla lines. When Bimbo moved the facility’s sweet baked goods production to its facility in Toluca, Mexico, it created the opportunity to invest in new equipment to meet rising demand for flour tortillas in Mexico City. The equipment was installed five years ago.

“We needed to produce tortillas in a faster way with more competitive pricing while still delivering a quality product,” said Jorge Zarate, global senior vice president, operations and engineering, Grupo Bimbo. “And the team at Santa María deserves to have one of the state-of-the-art production lines, and now they have that honor.”

The two tortilla lines mirror each other and only require three permanent operators to monitor them.

“It’s fully automated, which makes it a more continuous and uniform process,” Mr. Zarate said. “Food safety is assured, and the people who are needed to run the line are kept safe even though it’s a high-yield line.”

Ingredients are automatically scaled and added to the mixers. Dough is mixed for some minutes, depending on the product. It is then fed to the tortilla line, the latest technology.

Each production line houses two dividers, allowing each line to divide twice as much dough to really open up capacity.

Dough balls then travel through the intermediate proofer before being pressed and then baked in the oven. Baked tortillas pass through a cooler to achieve the appropriate temperature for stacking and packaging. Before they can reach the packaging line, however, each tortilla passes through a vision system. Tortillas that don’t fit the pre-programmed specifications are rejected.

Those tortillas that pass inspection are stacked and packaged by packaging lines, which feature baggers on each line to handle the capacity needed.

In all of Grupo Bimbo’s bakeries, Santa María included, quality checks are conducted continuously. Product is pulled off the line and scored around the clock to ensure that every batch is up to the company’s high standards. Walking through the bakery, visitors can see the progress throughout the shift at quality check stations on each production line.

Grupo Bimbo sticks to a training schedule to ensure all team members on the production room floor are empowered to fulfill their potential. Employees retain general manufacturing training as well as food safety, quality assurance and hands-on training for the various equipment and processes.

As the company has automated Santa María over the years, investing in equipment has been about improving efficiencies and maintenance as well as improving the lives of its employees.

Today, Santa María, like most of Grupo Bimbo’s facilities, employees use the Internet of Things to collect and track data to ensure the production lines are running efficiently and product is meeting quality standards. This also empowers the assets management team in their predictive maintenance schedule. And while production improvements are important, Raul Obregon, chief information and transformation officer, Grupo Bimbo, said the individual is always at the center of these investments.

“It’s not about digitization and robots and eliminating a position on the line,” he explained. “It’s about upskilling that person on the line. We want to give them the opportunity to train and be in an upskilled position. These are our values in action. As we deploy these technologies worldwide, that’s what we’re aiming for.”

This article is an excerpt from the September 2023 issue of Baking & Snack. To read the entire feature on Bimbo Santa María, click here.