NORWALK, OHIO — In the beginning, there was a bun line. That was in 1967 at New Horizons’ headquarters in Norwalk. Back then, the company was all about saying yes and being the best. A self-professed “baker’s baker,” New Horizons specialized in contract manufacturing for food service accounts and branded products.“We’ve never had our own label,” said Trina Bediako, president and chief operating officer at New Horizons. “We never wanted to compete with our retail customers.”

The bun line has been operating almost as long as the building itself, Ms. Bediako said. “We’re still improving on it; the line was totally redone in 2011,” she said. “Continuous improvement is paramount to our success.”

During its more than half a century in business, the bakery has not only significantly grown its physical space, but it also has streamlined the business and become one of McDonald’s largest producers of buns and English muffins, servicing restaurants east of the Mississippi river.

As with most things in life, the New Horizons journey to success was just as important as the destination itself.

The business was built on custom orders and its ability to nimbly produce and package any baked food a customer could dream up. “A customer would call, and we’d just say yes,” recalled Ms. Bediako, whose father Tim Brown, with more than 50 years in the baking business and the former Continental Baking Co., has been the chief executive officer for 23 years.

As the business grew, New Horizons was able to identify its core strengths and capitalize on them. To keep its commitment to the McDonald’s system and provide quality product supply, New Horizons has made some serious strategic moves to streamline its production and increase capacity in its plants in Fremont, Ind., and Toledo, Ohio, in addition to the flagship location in Norwalk.

“Each customer brings new challenges and requirements, but that keeps us focused and sharp along the way,” Ms. Bediako said. “As a result, ultimately, all parties benefit.”

Strategy in optimization

When a bakery finds itself at capacity, various solutions are available, whether it’s expanding the line — or even the physical space — or strategic restructuring from the outside in. New Horizons did both.

At Norwalk, it started out on a large plot of land, which provided ample room for growth when the bakery found itself out of capacity. What used to be called the “back 40” — as in the 40 acres surrounding the facility — is now jokingly called the “back 10,” thanks to so much expansion of the building.

In addition to the high-speed bun line, the Norwalk plant runs four English muffin lines and one bun line, while the Fremont facility houses two muffin lines and a hybrid bun-bagel line, and the Toledo operation, which New Horizons acquired only a few years ago, has capacity for three production lines.

Adding space isn’t always the answer to increasing capacity, though. Sometimes it takes a more calculated approach or even a full paradigm shift. Being a “baker’s baker” requires agility, but increased flexibility can come at the cost of efficiency. “We had to step back and look at our business and think strategically about which direction we wanted to go,” Ms. Bediako explained. “We chose to focus on efficiency and optimize our day-to-day operations.”

New Horizons was able to streamline operations and gain capacity through strategic optimization; the bakery made a difficult but tactical decision to move away from producing a plethora of products that had become so varied that basic changeovers were taking hours on end several times a week.

Streamlining changed all that. The bakery went from more than 100 stock-keeping units (s.k.u.s) to about 20 and, in the process, significantly reduced its changeover time.

“As orders come in, we’ve got to know the time we need and the capacity we have available at any given time to support those orders,” Ms. Bediako said. “It’s very different from where we were years ago. We have to look at the whole picture now; it’s a different view. All our customers have been very important to us, but at the end of the day, we have to do what’s right not only for our customers but also for the 500 employees who are relying on us to make the right decisions every day.”

Today, third-party production remains a part of the business, but the primary focus is on like products and long runs.

Muffins, muffins, muffins

Much of New Horizons’ increased business came in the form of English muffin production, prompting the company to expand the Norwalk plant by 5,500 square feet to make room for a fourth muffin line, bringing the company to six total English muffin production lines in all three facilities. In all, New Horizons produces about 2 million English muffins per line each day.

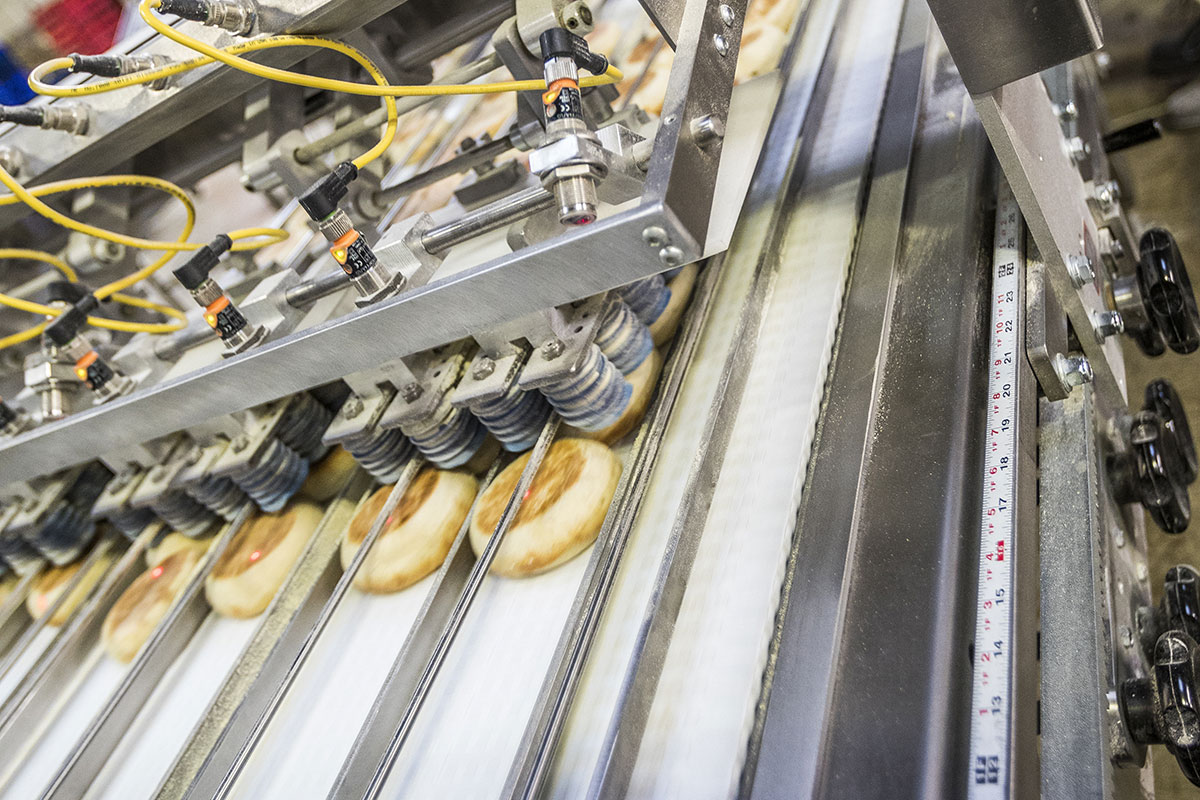

On the new line at Norwalk, English muffins begin with a base that’s loaded into a 1,600-lb Shaffer, a Bundy Baking Solution, mixer that makes about 1,800 dozen muffins an hour on 20-minute batches. Once mixed, the high-absorption dough — which functions a bit more like pancake batter — is released to an auger dough pump, which transfers it up to a conveyor belt where it heads to the hopper of a Vemag divider. This double-screw system portions the dough, and the waterwheel divider cuts it into six portions of roughly 70 grams a piece.

It then rounds dough balls that tumble down six lanes and through a Larimore cornmeal duster that includes a reclaim system to catch and reuse the excess. This is just one element of New Horizons’ sustainability efforts, as the system significantly reduces cornmeal waste as well as dust in the plant.

After the dough balls are aligned, they travel through the proofer for 25 minutes. New Horizons designed its proofer in-house, thanks to the efforts of Roger Hanson, vice-president of engineering, and the company’s longest-standing employee with more than 40 years of service.

“Roger has built his reputation by taking used equipment, rebuilding it and making it useable for operations,” said Rob Harrison, director of operations.

Over the years, Mr. Hanson’s expertise allowed the company to experience faster expansions. “The new muffin line would typically take one to two years to install, but Roger and his team got this one completed in six months,” Mr. Harrison said. “Because of that, we got to market quicker and at a lower cost. We wouldn’t trade his weight in gold.”

After the proofer, the dough balls are dropped into cups and travel through the griddle, which was manufactured in-house and uses Banner-Day burners and controls. Making the best use of the space, the band travels 5 minutes, flips the cups and makes another 5-minute pass back to the infeed side, where it discharges and begins the cooling process by running parallel to the griddle toward the cooling tower. To drop their internal temp by more than 100 F°, the muffins spend nearly an hour riding up the conveyor.

At the top, the muffins are transported to the next room, where they are integrated with the other three muffin lines for quality inspections in the EyePro System, which checks specs, including height, diameter, symmetry and color. Once they pass the vision inspection, it’s on to the LeMatic forker, where the conveyor runs through at about 200 feet per minute. Muffins spin four times while the forker perforates the product, and on to packaging they go.

New world packaging

Changes in New Horizons’ business naturally led to changes on the line because co-manufacturing and high s.k.u.s call for an entirely different packaging culture from that of fewer s.k.u.s and similar product types. At the end of the line, there’s an inverse relationship between flexibility and automation, so, the company’s strategic realignment called for optimization in packaging, as well. It meant moving away from flexibility and toward efficiency.

When all English muffins head toward the packaging area, two workers provide a final once-over to ensure the muffins are up to spec based on visual cues posted throughout the production area. From there, the products enter a LeMatic bulk packaging machine that vacuum-seal them 36 at a time.

But before they enter, plastic sponge hold-down cups line up the muffins to uniformly feed them. “The old style was hold-down feet, but LeMatic came up with this style, which is much more efficient,” Mr. Harrison said.

And in the name of efficiency for the customer, bulk bags are sealed not only on the sides but also in the center, blocking them off a dozen at a time. “That way, when the restaurant opens it, they only open 12 muffins at a time instead of exposing all 36,” Mr. Harrison explained. Once sealed, the 36-packs run through a Fortress Technology metal detector and are stacked into trays two at a time.

Here, New Horizons has recognized even more opportunities to streamline the process through automation. Soon, the operation will no longer run all lines into a common conveyor in favor of four separate units that will load the trays, stack them and run them to the palletizing area. “With feeding all the lines to one pack/stack, the problem was that we were running too fast,” Mr. Harrison said. “The timing just became too critical.”

The bakery is also in the process of manufacturing a fully automated palletizing module for muffin production that will be a mirror image of the bun palletizer. This will happen once it completes the shift to 100% bulk packaging (it currently packages a portion of English muffins in bags until the three additional bulk lines are installed).

Next, the pallets are shrink-wrapped in a way that supports another relatively new step for New Horizons: freezing.

From fresh to frozen

Once McDonald’s made the move to 100% frozen bakery products, New Horizons faced change. But oftentimes, change is good because growth soon follows. In 2017, the bakery added a 12,000-square-foot freezer expansion to accommodate the shift.

For many bakers, freezing is not without its benefits, especially from an inventory standpoint. “You can manage your supply,” Mr. Harrison said. “You can run your schedule the way you want, and you’re not at risk.”

Before the switch to frozen, these products were out the door the same day. “Now, I carry three-and-a-half days’ inventory in my freezer,” Mr. Harrison said. “Then the restaurants and the distribution centers carry inventory, as well. So, if a power outage or severe winter storm happens, you have time to react.”

Inside New Horizons, the world looks a lot different from the days when it was an exclusively fresh operation. “We’re sending out more than 75 trucks a week from this facility,” Mr. Harrison said. “That’s astronomical compared with what we did before.”

Freezing also has helped with clean label. In fact, Ms. Bediako called the industry trend toward healthier food “an area that all bakers have to acknowledge.” In terms of quality, formulating frozen baked foods makes life a bit easier. For example, operations can schedule long production runs and strategically build inventory levels.

Freezing delivers a fresher product, so long as the timing is right. At around 35 to 45°F, staling not only begins but it also speeds up exponentially. “Our goal is to get that product down to 20°F below zero within 8 hours,” Mr. Harrison said. “The faster we can get it there, the better the quality will be.”

The process starts on the pallet; shrink wrapping doesn’t cover the entire stack because the gaps help the cold air blow through and freeze faster. Inside the freezer, pallets sit in blast cells, where 20-mph wind is generated from fans in the ceiling. “When you blast, it’s all about air circulation,” Mr. Harrison noted. Although the goal is to freeze within 8 hours, this process can usually hit the mark in about four.

“As a McDonald’s supplier, going from fresh to frozen was a big jump for us,” Ms. Bediako said. “Our entire shipping and receiving department has its own heartbeat.”

For a bakery to remain successful after half a century in business, it must be willing to look inward, ask difficult questions — and accept the answers — and adjust accordingly. “For the short term, it’s about being stable and refining what we’re doing,” Ms. Bediako said. “We’ve had a good amount of growth this past year, and as we develop and perfect that, we ensure we’re on a solid platform for success. And that’s where the longevity comes from. If we don’t make our decisions appropriately as we go, then we lose the long-term success.”

Not only that, but it’s also about keeping an eye on the horizon, so to speak. “I believe we’ll always have some degree of growth,” she said. “But it will be controlled growth, not just for growth’s sake.”