Well before a package is propped up on a shelf, snack makers must consider how to safely get their snacks to the variety of bag sizes now available.

John Kuhnz, vice-president of Dorner’s engineering solution group, said focusing on grouping, routing, guides and transitions provides opportunities to increase efficiencies.

“If you don’t have your guiding or your transitions right, those bags will jam, and before you know it, you’ll have 200 bags on the ground,” Mr. Kuhnz said. “It’s really important that you’ve got a guiding product transfer and a system in place that can handle them.”

Delicate snacks like pretzels typically travel at slower rates than vertical form/fill/seal (VFFS) machines and baggers to minimize impact. Dorner installs high-sided rails or curtains to reduce the opportunity for jamming, twisting or jarring of the pretzels. They can also install powered side guides, essentially a conveyor tilted on its side, that moves at the same rate as the product to reduce friction. For transitions or gaps leading into a bagger, Dorner makes sure all transfers are level, and if there is a gap, it’s filled with a transfer roller.

Matrix, a ProMach company, uses its SmartGate technology to gently compact the charge of snacks as it comes off the scale to prep it for a bag.

“It compacts the charge into a cylinder then drops it into package,” said Christine Duncan, marketing manager, Matrix. “This allows machines to create those packages quicker and with more accuracy to make sure you don’t have any stragglers coming down the chute from the scale.”

Ms. Duncan said snack makers should match the bagging machine speed with the rates coming from the fryer and scale. Building in the opportunity to increase those speeds is also critical. If a product is bagged at 30 a minute now, plan on ramping up packaging as business grows.

“As you increase your speed beyond your ability to fill that scale, your bagger should be able to increase speed to keep up with that,” she said.

Right speeding for size

When implementing a smaller or single-portion packet, consider the processing capacity of other equipment on the line. Anurag Mitra, product marketing manager, TNA Solutions, said the fryer is likely to continue operating with the same capacity as before, even with a faster bagger.

“This means the equipment in use is usually the biggest obstacle to overcome when changing package sizes, so, investing in equipment with production flexibility as well as processing and packaging equipment that can complement each other’s output is the key to success,” Mr. Mitra said.

When implementing larger bag sizes like family packs, TNA recommends taking a holistic approach. Fryer output must be aligned with packaging speeds to avoid bottlenecks. With a fixed number of packaging lines, the fryer output must be divided between these packaging lines according to the required pack sizes.

Different bag formats require specific jaw systems. The TNA robag 3ci comes with single, double, rotary double, rotary triple and rotary flat jaws to provide the flexibility to handle different sizes and formats. The rotary double jaw configuration handles bag widths and lengths of up to 320 millimeters and 1,000 millimeters respectively while maintaining throughputs of up to 150 bags per minute. The rotary triple jaws are more suitable for smaller pack sizes and can produce 250 bags per minute.

With its small footprint, the robag 3ci can also be installed near each other, meaning one fryer can feed several packaging systems to increase throughput rates.

Smaller bags require more machines running at higher speeds, and that means the potential for more waste and more changeovers. Creating harmony between all pieces of equipment on the line is especially critical for these pack sizes.

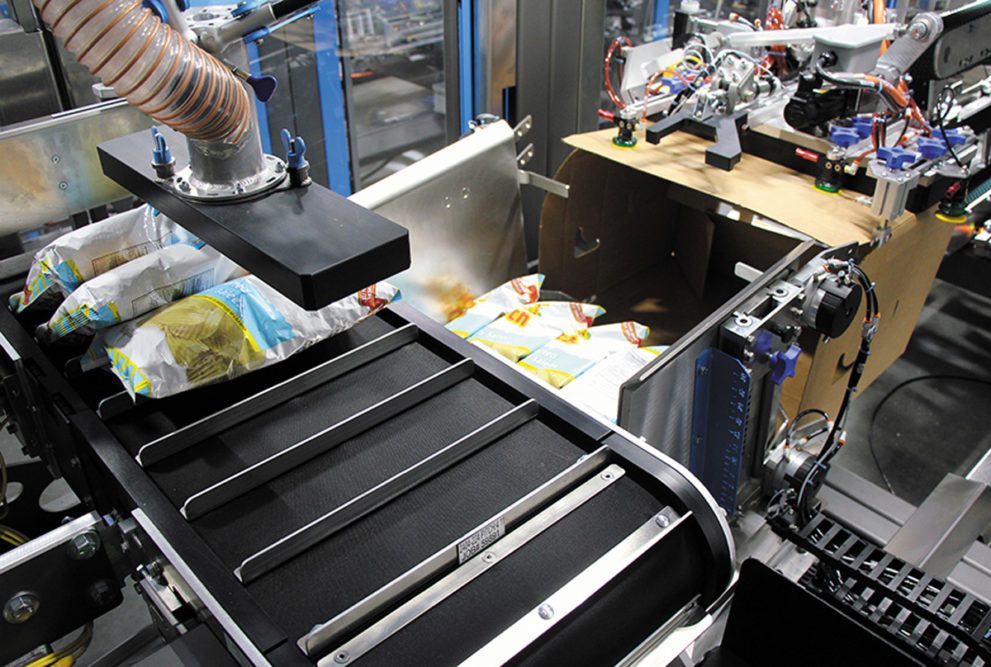

Heat and Control designs its baggers to provide a turn-key option at the end of a line. Jeff Almond, snack food packaging industry manager, Heat and Control, cited the company’s packaging cell as an example. It is comprised of a scale, bagmaker, seal checker and automatic case packer. It also controls important factors like proper bag air fill.

“We can monitor air fill in real time and feed information forward or backward to adjust in real time,” Mr. Almond said. “The net effect is better line efficiency and enables the operator to monitor more lines, reducing labor. We can employ several strategies to maximize line efficiency, including smart product accumulation, segmented recirculation, adaptive packaging and flexible automation.”

The speed difference between small packs and large ones varies drastically. For example, Ms. Duncan said a larger bag of snacks like chips might run at 40 bags per minute. It simply takes longer to fill larger bags without damaging the product. But changeover to a smaller 100-calorie pack, then that machine needs to run 80 bags per minute to match the output coming off the scale. To manage this huge differential, Matrix uses preprogrammed “recipes” for each package size. These recipes automatically adjust fill speed, film speed, seal speed and more. All these changes are stored in the HMI.

To keep up with expanding SKUs and to avoid bottlenecks, snack companies need to consider changeover times in addition to bagging speed.

This article is an excerpt from the June 2020 issue of Baking & Snack. To read the entire feature on snack packaging, click here.