Consumers’ awareness about carbon footprint and other green initiatives has prompted an increasing number of retail and foodservice chains to request that their bakery suppliers provide documentation about their sustainability programs.

The baking industry has responded by being one of the leading participants in the Energy Star program by the US Environmental Protection Agency.

The groundswell of interest in sustainability is also fueling the exploration of low-emission burners and heat recovery systems. Mecatherm, for instance, is developing advanced energy recovery systems that will be unveiled at iba 2023, the international trade show that runs Oct. 22-26 in Germany.

Franck Ellenbogen, sales director, North America, Mecatherm, explained that total energy consumption is always split between useful energy, which is used for heating products, and lost energy that’s used to heat oven walls, belts and fumes.

Ovens also spend a considerable amount of energy on airflow management. Mecatherm, he said, focuses on reducing energy losses and incoming fresh air management to create more sustainable ovens.

Mr. Ellenbogen suggested a hybrid or all-electric oven provides two main advantages. They either minimize or eliminate carbon dioxide (CO2) and nitrogen oxide (NOx) emissions.

Second, they decrease energy consumption because only low or no fumes are emitted.

Overall, electric oven technology has progressed significantly during the past few years, noted Phil Domenicucci, baking systems specialist, AMF Bakery Systems.

The operational advantages of electric heating, he said, include a fast response to set point changes, very even heat distribution and reduced maintenance,

On the other hand, the power use of electric ovens must also be considered because some bakeries do not have enough incoming power to run a large oven.

AMF offers electric burners for Vesta Tunnel and Tray ovens as well as the Den Boer MB-E Electric Tunnel ovens in sizes ranging from 800-mm (32-inches) to 4-meters (160-inches) wide and from 4.4-meters (14.4-feet) to 62.4-meters (205-feet) long.

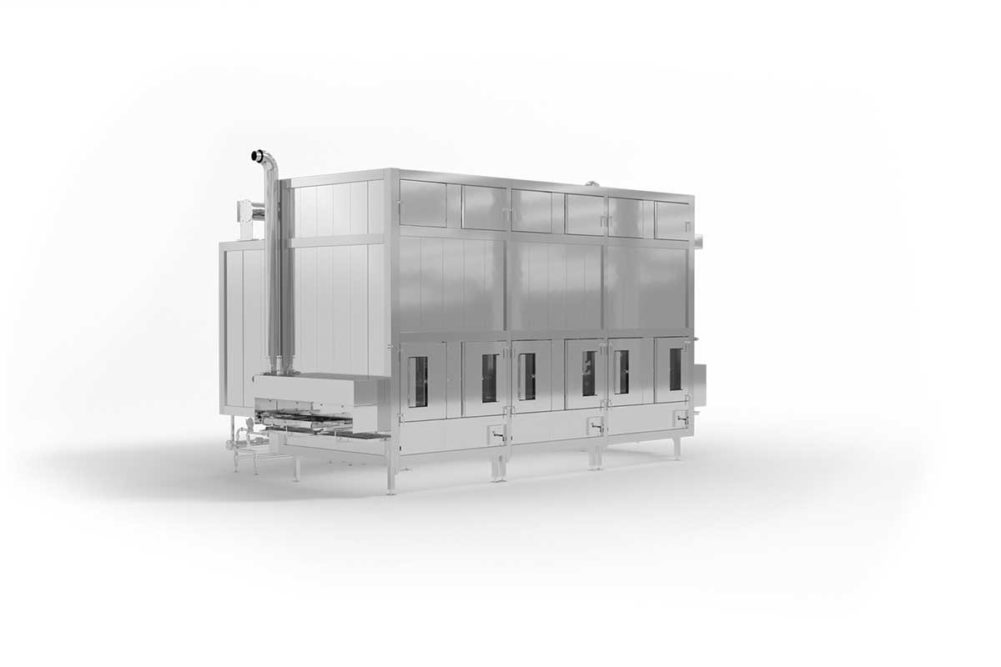

Mr. Ellenbogen said electric heat can lower energy consumption by up to 15% on Mecatherm ovens and reduce maintenance on burner and chimney ducts that’s typically needed for gas-fired ovens. He added vertical and tunnel ovens such as the company’s M-TA and FDA models can be switched to electric supply.

Electric ovens generally need less exhaust due to the lack of products of combustion, said Tyler Martin, R&D engineer, baking systems, Reading Bakery Systems (RBS).

He added extremely accurate proportional-integral-derivative loop controls help create a steady baking environment for product consistency, but also assist in maintaining constant energy consumption while eliminating large energy spikes.

Jerry Barnes, vice president, Babbco, pointed out electric heating efficiency is also greater due to modern silicon-controlled rectifier devices and almost unlimited control range.

“The significant advantage, though, is that oven exhaust can now be dialed much lower, retaining more heat in the bake chamber,” he said. “Equipment uptime is improved, as gas safety devices, gas trains and the necessary expertise to maintain them goes away.”

A bakery’s location goes a long way in whether to go electric, said Ken Johnson, president, Gemini Bakery Equipment. Internationally, it makes sense in some countries.

“The primary advantage when replacing fuel heating with electric elements is that the exhaust gas losses from the oven are eliminated,” he explained. “This results in a 12% to 15% energy savings. The primary disadvantage when using an electrically heated tunnel oven in North America will most likely be the cost of the electricity required. All products that can be baked in a gas-fired indirect tunnel oven can be baked in an indirect electric-fired tunnel oven provided that the electric heating elements are properly sized for the application.”

When it comes to baked snacks, an electric oven’s performance is similar to a gas-powered one. That’s what RBS discovered after installing an oven at its innovation center and running organoleptic tests and pilot research and development on snacks.

“We saw that the same snacks can be successfully made on the electric-powered oven and with the same quality, textures and taste,” Mr. Martin recalled. “While the electric oven is slightly less responsive to a temperature adjustment, the baking process is more energy efficient due to less products of combustion and less humidity needing to be exhausted.”

This article is an excerpt from the August 2023 issue of Baking & Snack. To read the entire feature on Ovens, click here.