Pro Tip: Roasting shows promise as a thermal pre-treatment for various types of pulses to favorably enhance bread-making properties.

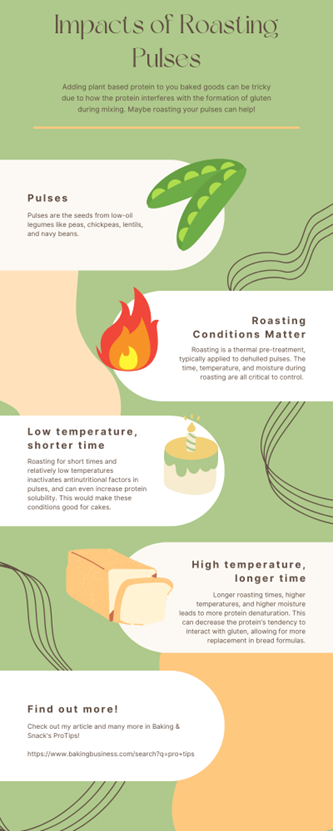

Consumers are demanding high-protein baked goods, which has led many bakers to explore the possibility of adding low-oil legumes (pulses) into their formulas. However, especially when adding pulses such as peas, lentils, chickpeas or the plant-based proteins isolated from these sources, the dough can become sticky and hard to manage, and consumer acceptability decreases.

These changes happen for many reasons, but two common issues are that the non-wheat proteins interact with the developing gluten matrix during mixing preventing it from forming correctly. These added protein sources compete for water during mixing, leading to under-hydrated gluten that does not adequately develop.

Recently, several research groups have evaluated different ways to treat pulses, including peas, lentils, chickpeas and navy beans. Roasting whole seeds has emerged as one strategy that can lead to enhanced baking properties from the flour that is later produced.

Source: Harrison Helmick

Source: Harrison HelmickRoasting typically involves dehulling pulses followed by a thermal treatment step before grinding the seeds with traditional milling equipment into flour.

In some cases, the roasted pulse flour is further processed to extract the protein. Roasting can lead to a modest increase in protein yield from pea flour when roasted at 150°C for 10 to 20 minutes, but the yield decreases significantly if roasted for longer than this. Interestingly, protein isolated from roasted peas had higher levels of purity than unroasted peas, showing less contamination from carbohydrates and lipids.

The temperature, time and moisture content during heat treatment are all important parameters to consider when seeking to optimize the functionality of the protein in the flour or isolate.

If the goal of roasting is to deactivate antinutritional factors that are naturally present in pulses, such as trypsin inhibitors that interfere with the body’s ability to digest proteins, roasting pulses tempered to 14% moisture at an internal temperature of 80°C for one minute is all that is required.

With these short times and low temperatures, relatively little change is seen in the functional properties of the protein. In the case of chickpeas and yellow peas, these conditions led to an increase in protein solubility and emulsion activity as the result of the treatment.

When increasing the time, temperature and moisture applied during roasting, there is an increase in the degree of denaturation seen in the proteins. In most cases, this decreases protein solubility and requires more protein to form gels, which could decrease the applicability in products such as cakes.

However, the denaturation observed in these more aggressive processing conditions can lead to relatively inert protein that does not interact as much with gluten, allowing for higher levels of incorporation into bread formulas.

This was shown in several bread baking studies, where roasting at temperatures between 150°C and 180°C for 10 to 20 minutes led to better bread-making properties than unroasted pulses.

In comparing roasting to other thermal and non-thermal treatments, including sprouting and boiling, roasting led to the best loaf volume in formulas that replaced 30% of the wheat flour with pulse flour from pea and chickpea, which significantly increased the protein content of the bread.

Nearly the full original volume of wheat bread could be recovered when 5% vital wheat gluten was incorporated into pulse-rich doughs; chickpea had the best loaf volume followed by yellow pea, lentil and then navy bean flour.

The yellow pea bread made under these conditions also had a similar count of air cells in slices of baked bread but was harder in textural analysis. In terms of sensory testing, a combination of roasting at 140°C and 10% added steam to the roaster led to bread with the least detectable off flavors and greatest overall sensory scores.

Overall, roasting shows promise as a thermal pre-treatment for various types of pulses to favorably enhance bread and cake-making properties, as long as the time, temperature and moisture of the product are optimized for the products in which these flours will be used.

Harrison Helmick is a PhD candidate at Purdue University. You can connect with him on LinkedIn.

His research is conducted with the support of Jozef Kokini, Andrea Liceaga, and Arun Bhunia.