Maintaining clean equipment not only ensures that the food running through freezers stays safe but that the machinery also runs smoothly. Part of that is minimizing frost buildup.

“The primary bottleneck within freezing is frost building up on the evaporator,” said John Bauer, PNA freezer product manager, JBT Corp. “because it blocks the air from entering the evaporator and for that heat exchange to take place.”

The evaporator, or coil, handles the heat exchange in freezers. The refrigeration runs through the heat exchanger, removing heat that the air picks up from the baked goods.

“For us, the most obvious way is to use a method of continuous coil defrosting,” Mr. Bauer explained. “We’ve developed a few different methods over the years. Probably the simplest one is what we call a mid-shift defrost. The coil can be defrosted during a break. If workers go on lunch break, they actually stop production or put the freezer on hold and just defrost the coil. This will give them probably 50% to 75% more coil life or run time for production.”

The most common and most effective defrosting method in the bakery industry is sequential defrost, Mr. Bauer said. Air defrost is a less expensive option, but it provides two to three weeks of runtime for most bakery applications vs. months with sequential defrost.

“In air defrost, we use clean, dry compressed air to shatter frost off the coil,” he explained.

In sequential defrost, production can continue to run uninhibited while one of the multiple coils is defrosted in sequence. Mr. Bauer said he’s seen producers operating for months between shutdowns using this method.

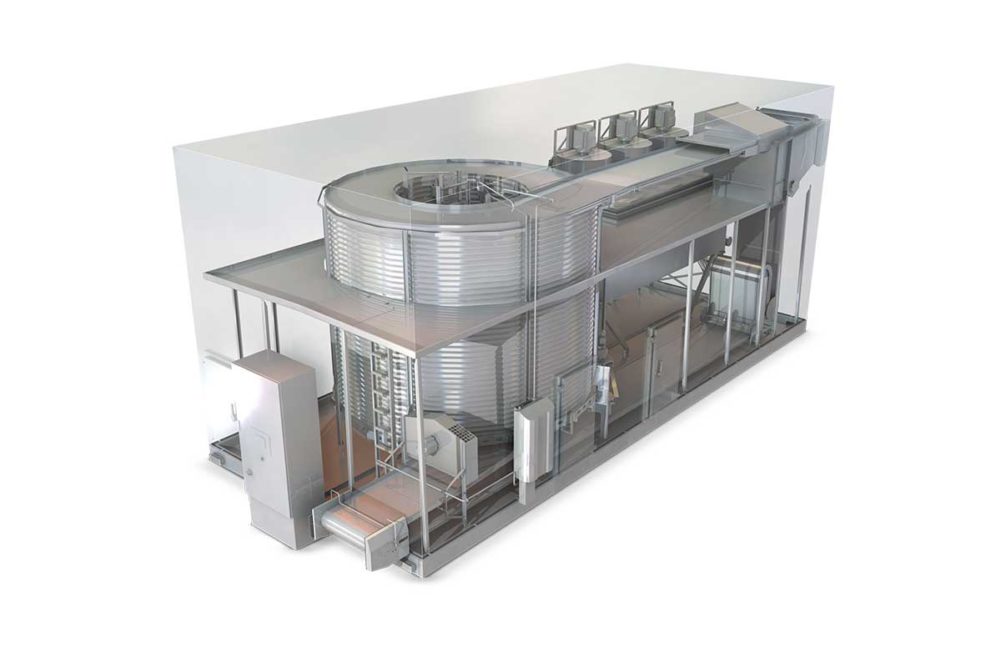

Proper maintenance of the spiral tower extends the life of spiral freezers, including adjustments needed to evaporator fans and defrosting systems, said Wim Littel, executive director of LTI, which partners with AMF Systems in the manufacture of its Vesta Spiral Freezer.

“As a result, these things are less heavily loaded and the interval between maintenance sessions can be extended,” he explained.

Many freezers currently only have a cleaning brush and need to be cleaned with a pressure washer, which takes a lot of time, said Maarten van der Coer, sales director, Verhoeven Bakery Equipment Family.

“About 50% of our freezers are sold with a CIP (clean-in-place) installation as well as an automatic cleaning program, which drastically reduces cleaning time,” he explained. “After the production is finished, the freezer is heated up quickly so that all the frozen ice in the freezer thaws quickly, and the automatic CIP program then cleans the freezer quickly and automatically.”

With metal conveyor belts, sanitation is straightforward, said Jeff Fontaine, product manager for Wire Belt Co.

“With the metal belt, it’s easily cleanable with a pressure washer to ensure that there’s no contaminants on the belt,” he said. “Also ensure your maintenance technicians are trained on all of this. You want them to know how to clean belts and how to install or repair a belt if it needs to be repaired.”

Even freezers with CIP systems can be tough to clean if they need to be scrubbed.

“We like to tell people if you have a belt, it’s running through a car wash, which is what a lot of these CIP systems are,” said Jonathan Lasecki, director of engineering, Ashworth Bros. Inc. “So we need to have something that’s very open, that allows rod movement, belt movement, product movement, so as you spray it, any product that’s in there can be dislodged.”

Bryan Hobbs, director of Ashworth Factory Service, recommended that people run lubricated rags with detergent between the belt and rails and wipe down rails rather than just spraying water on equipment.

“If you think about washing your dishes at home, if you put a little elbow grease into it, you get a lot further than you do spraying water at it,” he said.

Spiral freezers can be tall and in tight spaces, which could present challenges for cleaning.

“You might have to take the belt completely off, especially with those heavier belts,” Mr. Fontaine said. “A lot of times customers will call the OEM and have them come out and take off the belt and then reinstall it because it can get a little tough to do this without the proper equipment.”

OEM and belt manufacturer teams can also be called in to provide a full system evaluation to ensure that the equipment is right for the application while providing recommendations for optimization based on needs, said Matthew Pierotti, global product marketing manager, Regal Rexnord.

Nicola Menardo, president, TP Food Group — North America, noted that one recurring mistake he sees is producers incorrectly using cleaning solutions, such as failing to dilute concentrated products as directed. Sanitation crews can also fail to rinse down equipment properly after cleaning.

A common mistake that Mr. Pierotti sees is the rough handling of conveyor belts, such as walking or standing on the belt.

He also cautioned against do-it-yourself sanitation being performed by workers who are not well trained, which could lead to the shortening of the belt life.

This article is an excerpt from the October 2023 issue of Baking & Snack. To read the entire feature on Cooling & Freezing, click here.