Total cost of ownership means making it clearer for operators to see what they’re cleaning while eliminating areas where dough or water can collect or be trapped.

That’s why companies like AMF Bakery Systems have pushed to simplify their mixers from a design and operational perspective.

“Taking the complication out of the equipment is one of the drivers today,” said Terry Bartsch, executive product manager, AMF Fusion, an AMF Bakery Systems brand. “We all know that there is a difficulty in the workforce, not only with operators but also with maintenance and sanitation people. There are more demands on bakers today to keep their equipment properly cleaned, and it’s up to us to keep up with those demands.”

From a maintenance perspective, he added, it means ensuring easy access to bearings so greasing them is quicker or eliminating the number of spare parts.

“From a labor standpoint, AMF uses a gearbox tilt mixer that requires a lot less maintenance because you only have to maintain the gear motor that’s running about four times an hour,” Mr. Bartsch said.

With the move toward larger batches and stiffer doughs, he added, belt drives can provide shock-absorbing protection to the gearbox to make them last longer.

“You’re going to get seven to 10 years on the belt before you have to replace it,” Mr. Bartsch said. “As a result, you’re only going to change the belt two to three times over the 20-year life of that mixer.”

Escher Mixers, acquired by Middleby Bakery recently, offers a double-stop transmission with two belts designed to deliver more torque to various mixing tools as the dough stiffens during development.

“Typically, the firming of developed dough during the last 2 minutes of mixing significantly increases the friction generated by the tool and the dough, which could cause a belt to slip,” said Alessandro Cosaro, Escher’s founder. “Having larger pulleys and a double set of belts drastically increases the life of the belts.”

He said Escher’s industrial mixers, which hold up to 800 kg (1,760 lbs), rely on a positive-driven, conical system that eliminates slippage that can cause wear and tear.

“We have reduced the maintenance as much as we can to avoid any breakdown,” Mr. Cosaro said. “That includes an automatic greasing unit inside the mixer that lubricates the bearings. The unit’s PLC sounds an alarm if the greasing system fails or if grease tanks are empty.”

To avoid pricey breakdowns, bakeries rely increasingly on PLCs, HMIs and an alphabet of digital controls to monitor and maintain a mixer.

“It’s not new, but we have menu-selective screens to set up parameters and even CIP parameters that are integrated with our mixing equipment,” said Bob Peck, vice president of engineering, E.T. Oakes

For enhanced security, he added, E.T. Oakes also offers RFID readers where operators use a card instead of a password.

Many controls send out reminders about regular preventive maintenance tasks, such as checking agitator bearings or changing the oil in a gearbox, based on the run time of the mixer.

“We prompt the maintenance personnel to do a task instead of the old pen and paper system where it can be easily overlooked, and then it’s too late when a problem arises that can lead to catastrophic failures,” noted Marc Ferree, technical sales manager, Shaffer.

The latest in technology is also providing workforce savings. In bakeries with extended fermentation processes, automated guided vehicles (AGVs) can save labor with less infrastructure than in the past.

“The AGV will transfer the bowl from the mixer to the retarder and later to the bowl hoist,” said Ronald Falkenberg, regional sales director for USA and Canada at Diosna. “It’s actually not complicated. AGVs are like self-driving forklifts. With one AGV, you can stack the mixing bowls onto a shelf for resting, or a simple AGV will transport the dough from point A to B or from point B to C.”

AGVs have been around for years in warehousing and packaging departments, but they have increasingly become more commonplace in automated bakeries.

“If you have a 24/7 or 24/6 operation, you save at least three employees per shift,” Mr. Falkenberg explained. “More often, it’s more than that if you have a fully automated system with automatic scaling as well. Usually, you have two or three people per shift in the mixing area. With three shifts, you can save up to nine people per day.”

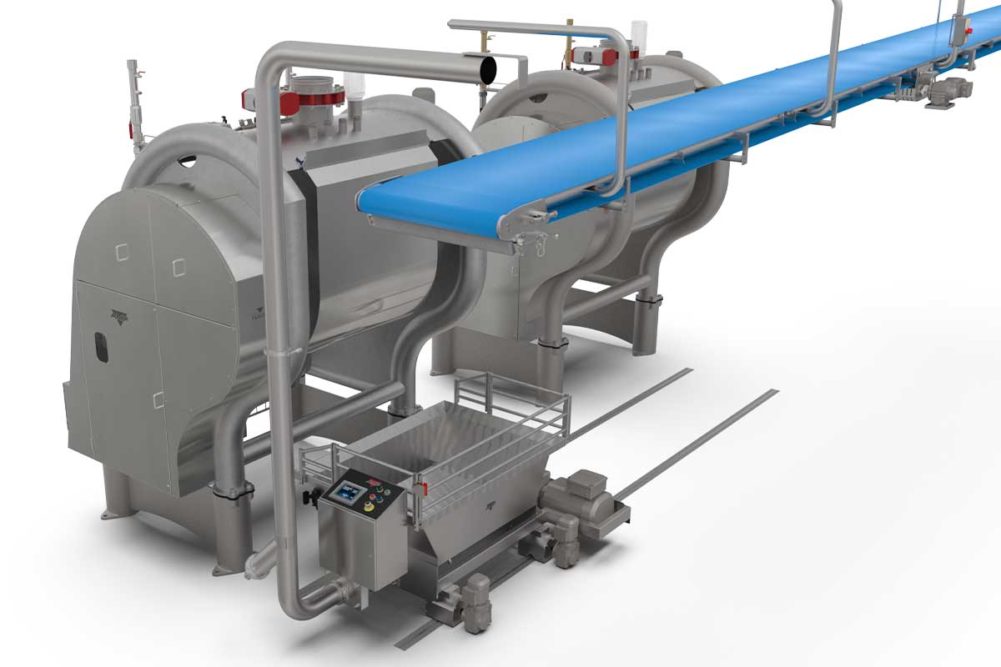

Some operations may even opt for automated fermentation systems to deal with long-term labor issues. Zeppelin Systems USA, for instance, offers fermentation systems for sourdough production, liquid sponge, poolish, sponge-and-dough or soaked grains.

David Rodrigues, regional sales engineer at Zeppelin Systems USA, said the fermentation systems include handling raw materials as well as scaling and blending of ingredients in the DymoMix pre-hydration and mixing unit. He added the systems also monitor the process to ensure recipes are always delivered as planned.

For cost-conscious bakeries seeking to invest in the long run, TCO provides a formula that incorporates everyday operating expenses into the capital spending process.

“Everyone is looking to reduce manufacturing costs,” Mr. Ferree said. “If we can design the equipment so it’s easier to clean and maintain, this can drive down the TCO of the equipment.”

This article is an excerpt from the May 2023 issue of Baking & Snack. To read the entire feature on Mixing, click here.